Heated Platen Press Manufacturer

All parameters, structure, appearance, and more of our heated platen press can be customized to your specifications.

Intelligent Temperature Control

High-Speed Processing

Energy-Efficient and Low Noise

Rapid Heating

High-End Components

Excellent Cost-Performance Ratio

Long Service Life

Quick Cooling

Exported to Multiple Countries

Customizable Machines

Video

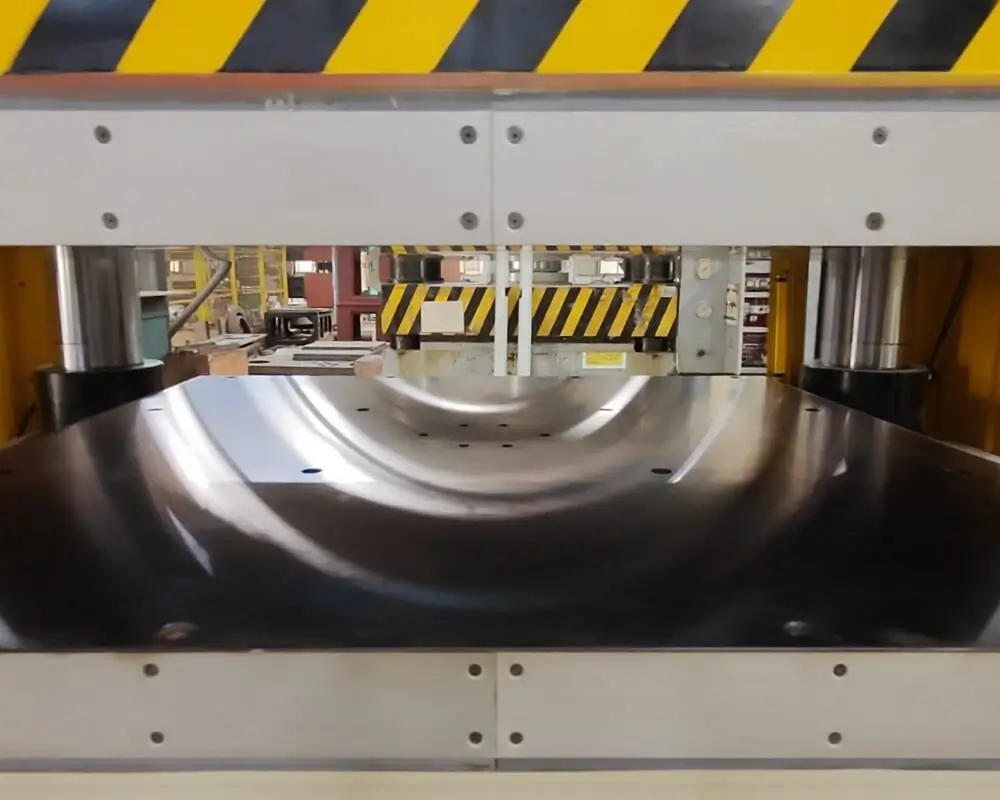

Front View of the Heated Platen Press

Hydraulic Cylinder:

Polished and chrome-plated high-strength hydraulic cylinders, paired with SKF seals, ensure durability and stability.

1 of 8Pneumatic Safety Guards:

Equipped with pneumatic safety guards, ensuring operator protection and heat insulation.

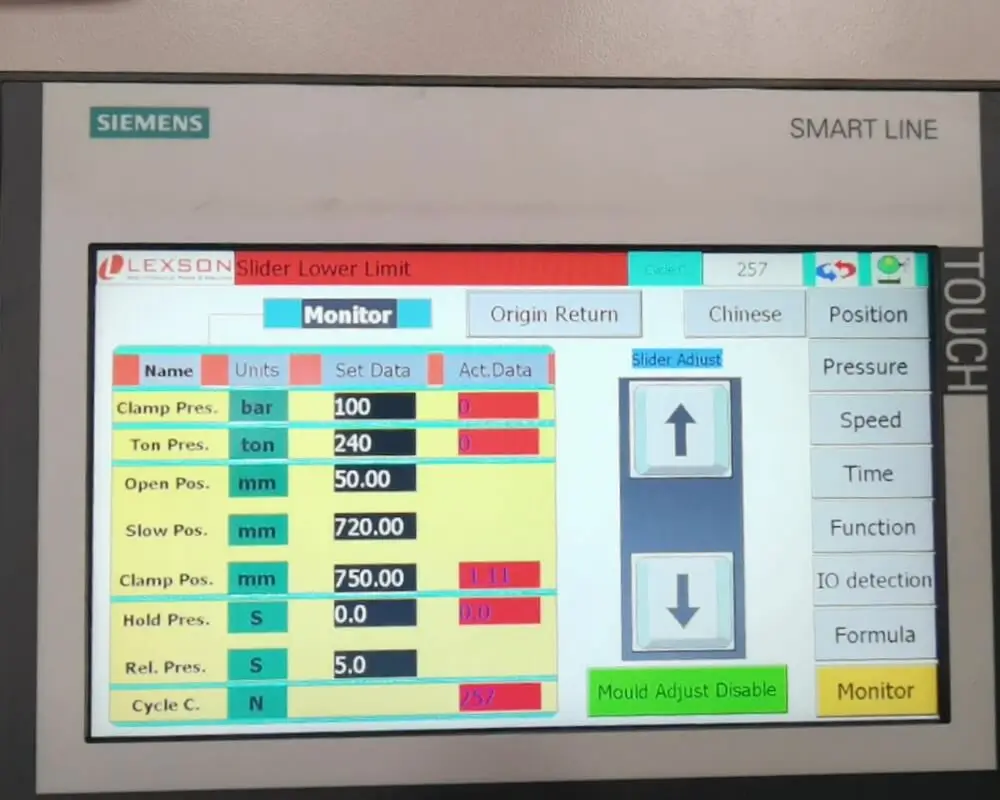

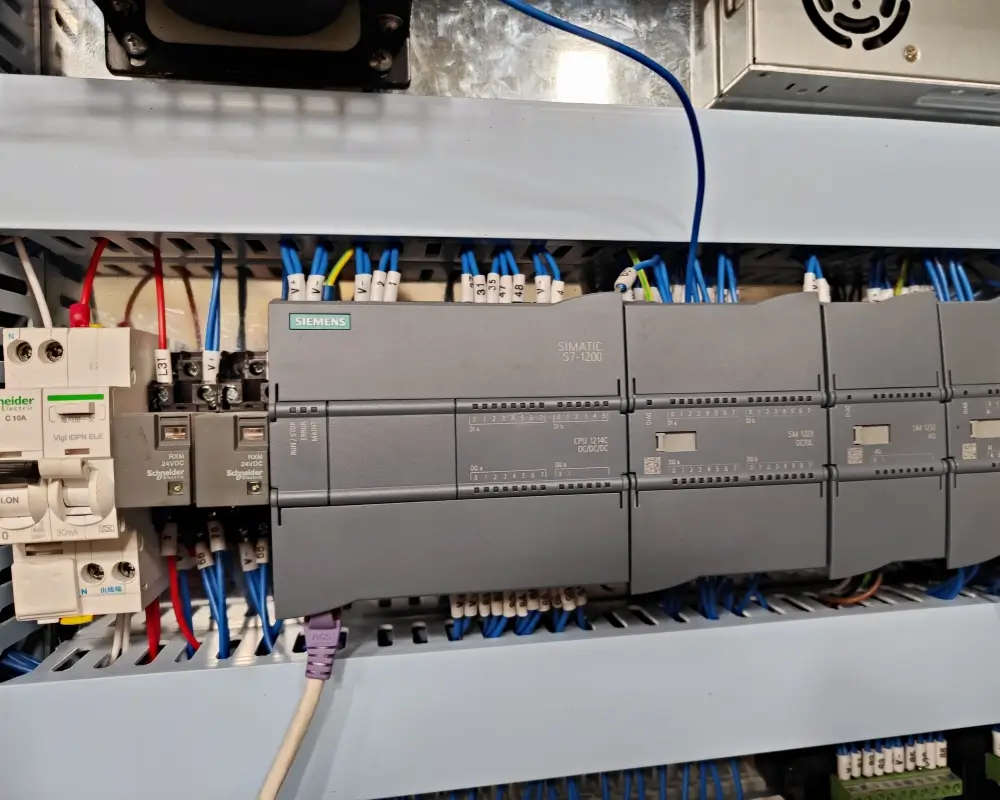

2 of 8Control System:

Our heated platen press is equipped with Siemens touchscreen and PLC. Intelligent temperature control system, rapid heating and cooling. Feature-rich and user-friendly.

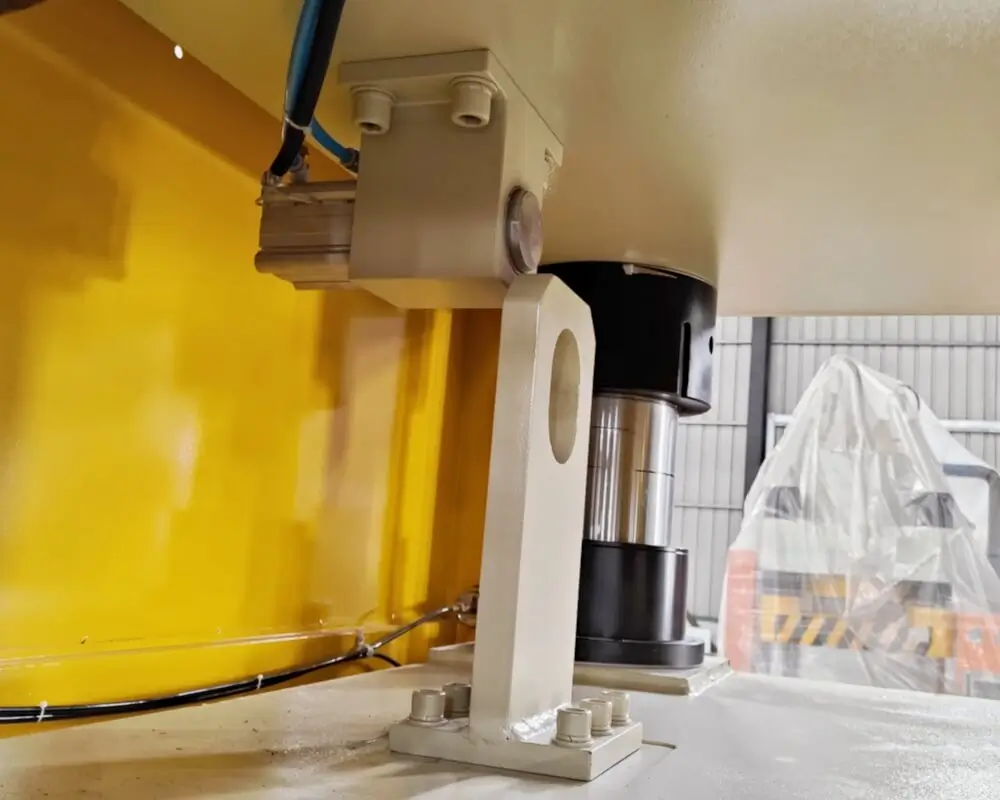

3 of 8Displacement Sensor:

Italian GIVI displacement sensor with accuracy up to ±0.005mm, ensuring absolute precision assurance.

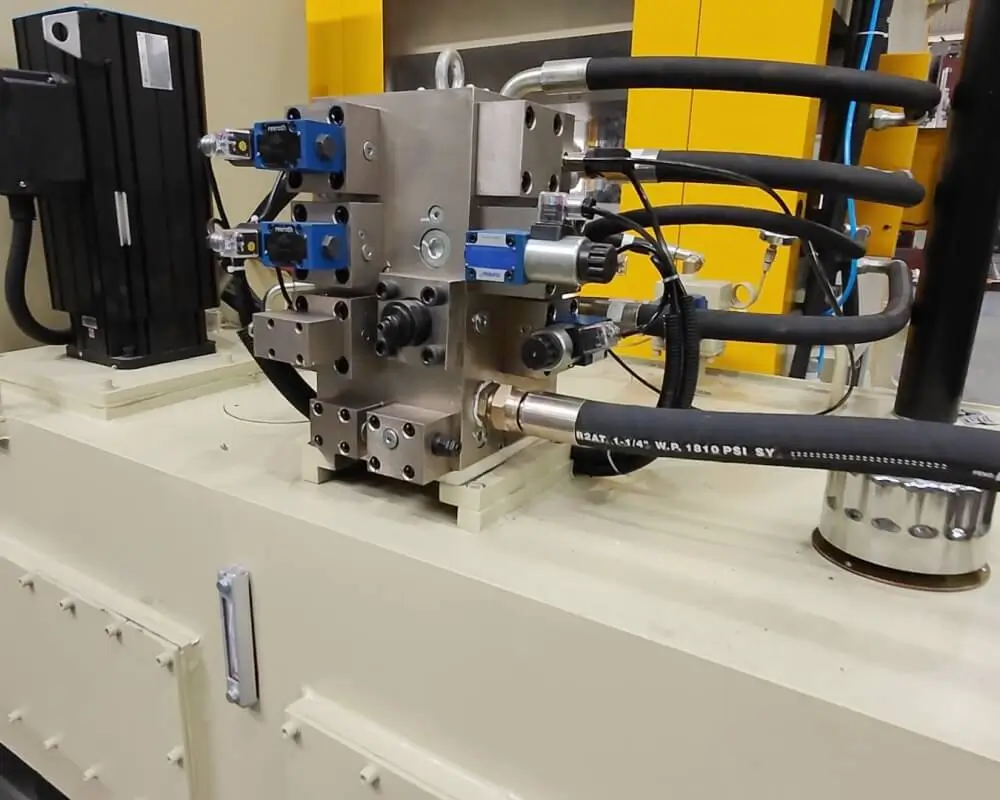

4 of 8Hydraulic Unit:

The hydraulic system primarily originates from top German brands. This high-integration system with fewer pipelines offers strong stability, ensuring precise control and minimal risk of oil leakage.

5 of 8NEMA standard electrical cabinet:

NEMA standard electrical cabinet. Main components sourced from top French and German brands, designed to protect the interior from dust and fibrous materials, with a surface treated for corrosion resistance. Suitable for most industrial environments.

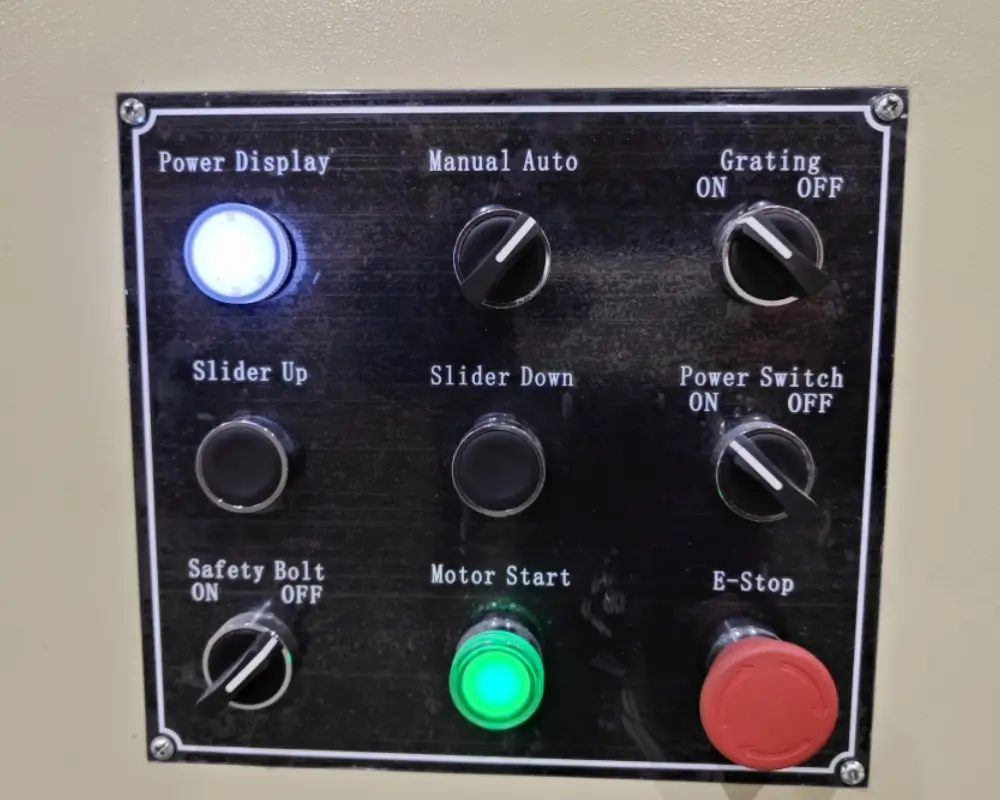

6 of 8Dual start buttons and emergency stop button

7 of 8Upper and lower heating plates:

The upper and lower heating plates are optionally available for electric or oil heating and are equipped with a cooling system. Our system’s heating and cooling capabilities are at the forefront of the industry.

8 of 8Machine Parameters

- 10 to 2000 tons of pressure.

- Power saving 50%.

- 30% increase in production efficiency.

- 20% of the machine heat compared to traditional hydraulic press.

- 30% faster heating and cooling speed.

- Eightfold safety assurance.

- Heating temperature can be customized.

- Positioning accuracy ±0.01mm.

- Machine designed for decades-long service life.

- Pressure error ±1 bar.

- linear displacement sensors accuray up to ±0.005mm.

- 20% cheaper than competitors.

- 20% lower oil temperature compared to traditional hydraulic press.

- Zero recorded major safety incidents.

Additional services

Offering customized solutions for heated platen press.

Integratable automatic feeding system, integratable robotic arm.

Offering machine OEM services.

Exterior of the Heated Platen Press

Our heated platen press features a customizable machine structure. By default, it features a 4-column, 3-beam design with an upper hydraulic cylinder and the option to include a center ejector cylinder. The machine’s body is constructed from high-quality low carbon steel, while the hydraulic columns are equipped with graphite-impregnated bronze bushings and hard chrome plating, ensuring long-term maintenance-free operation. Optional pneumatic safety guards are available to ensure the safety of operators during the heating process.

Lexson Machinery’s heated platen press is designed with the consideration of prolonged operation in high humidity and high-temperature environments. It undergoes treatments such as rust-resistant paint or blackening, as well as galvanization, ensuring that the machine is designed for long-term stability and use.

Control System and HMI

The heated platen press utilizes a closed-loop control system with real-time feedback throughout the entire process, ensuring precision and control in the manufacturing process. The HMI is feature-rich and user-friendly.

- It features a touch screen and PLC from Siemens, Germany.

- The machine offers an automatic operation mode and can be integrated with automatic feeding systems and robotic arms.

- Adjustable parameters include stroke, pressure, speed, dwell time, and multi-zone temperature control.

- It offers comprehensive data monitoring.

- Equipped with tricolor indicator lights and an alarm buzzer.

- The pressing and heating algorithms are specifically optimized for the heated platen press, providing precise and intelligent control.

- The control system coordinates displacement sensors, pressure sensors, and temperature sensors, forming a closed-loop control system.

- The repeatable positioning accuracy is as high as ±0.01mm.

Heating Plates

- The heated platen is preheatable and includes both upper and lower heating plates. It supports multi-zone heating with individual temperature control and monitoring. Equipped with upper and lower ceramic insulation boards, the heating platen is sealed on all four sides with ceramic insulation boards.

- Customized high-standard carbon fiber heating tubes ensure rapid and uniform heating and cooling, significantly enhancing production efficiency, and leading the industry.

- Equipped with temperature alarm and automatic shutdown functions in case of temperature anomalies.

- Equipped a water cooling and air cooling system for the heated platen, automatically activating after operation.

- Customization options include multi-layer heated platens, allowing simultaneous pressing of multiple workpieces.

- Equipped with a high-power exhaust fan or an oil fume extractor, along with a gas duct system, to efficiently collect the substantial amount of steam, smoke, and other gases generated during the operation of the heated platen press.

- The heating platen is easy to disassemble, making it convenient for re-polishing. Heating element components can be easily and quickly removed and replaced.

- The insulation protection of the heating element cables is suitable for high-temperature, high-humidity, and chemically corrosive environments.

Safety Components

Our heated platen press is equipped with industry-leading safety systems that meet safety standards in multiple countries. Lexson Machinery has always prioritized production safety, and our machines come with various safety components, ensuring over 30 years without any major safety incidents.

- Anti-tie down-Anti repeat circuit with dual channel monitored safety relay.

- Equipped with Japan’s SMC anti-drop cylinder device.

- Equipped with dual start buttons.

- Equipped with CT4-type safety light curtains, covering all entry and exit points.

- Emergency stop buttons are located at the front and rear of the heated platen press.

- Contactors open in case of temperature loop failure (control circuit malfunction) or other abnormal conditions.

PM Servo Motor

The heated platen press is equipped with an Italian PHYSIS servo motor. This permanent magnet synchronous motor boasts a high energy efficiency ratio, offering greater energy savings, higher control precision, quieter operation, and faster response times. The energy-saving characteristics are particularly crucial for high-power heated platen presses. These presses are equipped with heating and cooling systems, which increase their power requirements. As a result, the energy-saving benefits of the servo motor become even more pronounced, potentially leading to annual savings of thousands to tens of thousands of dollars in electricity costs.

- 50%-70% energy savings compared to regular motors.

- Utilizes a brushless design, reducing noise levels by 50% compared to regular motors.

- 50% less hydraulic oil consumption compared to regular motors.

- 30% improvement in production efficiency.

- Maintains oil temperatures 5-10°C lower than conventional motors with the same power output.

Hydraulic Components

Lexson Machinery’s heated platen press utilizes an advanced closed-loop hydraulic system, achieving precise flow and pressure control. The hydraulic system primarily features components from top-tier German brands, incorporating leak-proof and shock-resistant designs to guarantee long-term reliability. It achieves high-speed closing, low-speed profiling pressing, and high-speed backstroke.

- Equipped with SKF sealing rings from Austria, ensuring excellent sealing performance and long service life.

- Equipped with hydraulic valves from Germany’s Bosch Rexroth.

- Features a quiet oil pump from ECKERLE, Germany.

- Equipped with an oil filter that effectively removes impurities from the oil, with alarms for filter clogging and other anomalies.

- Equipped with an oil-water cooling system.

- Equipped with an oil leakage alarm system.

- The hydraulic system is equipped with safety valves and hydraulic support insurance circuits, effectively ensuring the safety of the machine and the operator.

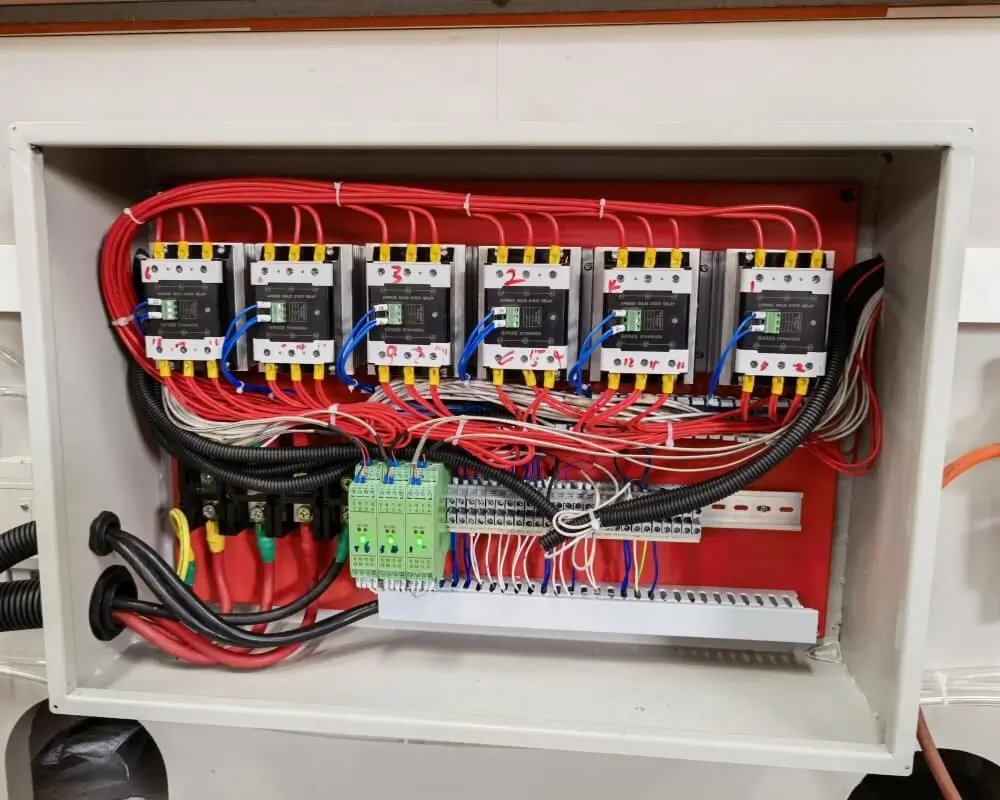

NEMA Standard Electrical Components

The heated platen press adopts NEMA standard electrical cabinets. These enclosures are designed with careful consideration for the complexity of the operating environment, ensuring excellent heat dissipation, interference resistance, and shock resistance.

- Comprehensive electrical circuit protection functions are in place.

- Equipped with interlock safety switches.

- Configured with high-speed debris-resistant cooling fans (inlet and outlet).

- Electrical components are sourced from Schneider Electric in France.

- Equipped with INOVANCE servo drivers from China.

- The cable protection box is specifically designed for the heated platen press, offering ample waterproofing, moisture resistance, and heat resistance.

Machine FAQs

What is a heated platen press?

A heated platen press, also known as a hydraulic hot press, is an industrial machine used to thermally mold thermosensitive materials or bond them with other materials under high-temperature and high-pressure conditions. This machine features heated platens, which can be heated to specific temperatures using either electric heating or oil heating. By setting a specified pressure and holding time, it applies continuous pressure and heat to the workpiece, enabling it to achieve the desired product process.

How high can the temperature of a heated platen press go?

The temperature range of the machine can be customized, with temperatures typically staying below 800 degrees Celsius.

What is the lead time for the machine?

The machine has a lead time of 25-35 working days.

What materials can the heated platen press handle?

The heated platen press is widely used for materials such as plastics, rubber, metal sheets, wood, carbon fiber, resins, composite materials, and more.

The pressure precision of the heated platen press? What is the accuracy of the heating temperature? What is the repeat positioning accuracy?

The pressure accuracy of the heated platen press is ±1%, the heating plate temperature accuracy is within ±0.5 degrees Celsius, and the repeat positioning accuracy is ±0.01mm.

What are the requirements for the working environment of the heated platen press?

A dust-free, dry workshop is recommended. The machine can operate in extreme conditions at 60 degrees Celsius with 90% environmental humidity.

Benjamin Parker –

The heated platen press has significantly improved our manufacturing process and greatly reduced our waste rate. I am very satisfied.

Matthew Johnson –

I purchased Velxun’s machines while working in China, and now that we’ve moved to the United States, we continue to choose them. The quality remains consistent.

John Kennedy –

Our business is rapidly expanding, and this is my third purchase of Velxun’s heated platen press.

Daniel Wilson –

As a brake disc manufacturer, we’ve finally found a machine that matches our needs perfectly, effectively resolving some of the finer production issues we’ve encountered.

James Cook –

The design solution for the hydraulic hot press is very mature, and our production capacity has increased significantly. We look forward to future collaborations.

Robert Young –

The sales team has been very patient in addressing our inquiries, providing us with various solutions. We are very grateful.

David Brooks –

The temperature control of the hydraulic hot press is very precise. I have confidence in Chinese manufacturing.

Nicholas Ford –

It’s not only of high quality but also cost-effective, it’s half the price of our country’s suppliers.