Custom C Frame Hydraulic Press

Video

Components of C Frame Hydraulic Press

Hydraulic Columns:

Four high-strength chrome-plated columns ensure low-wear operation for millions of cycles.

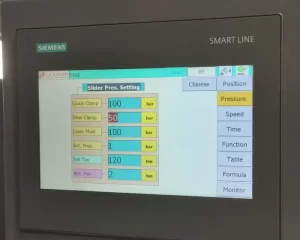

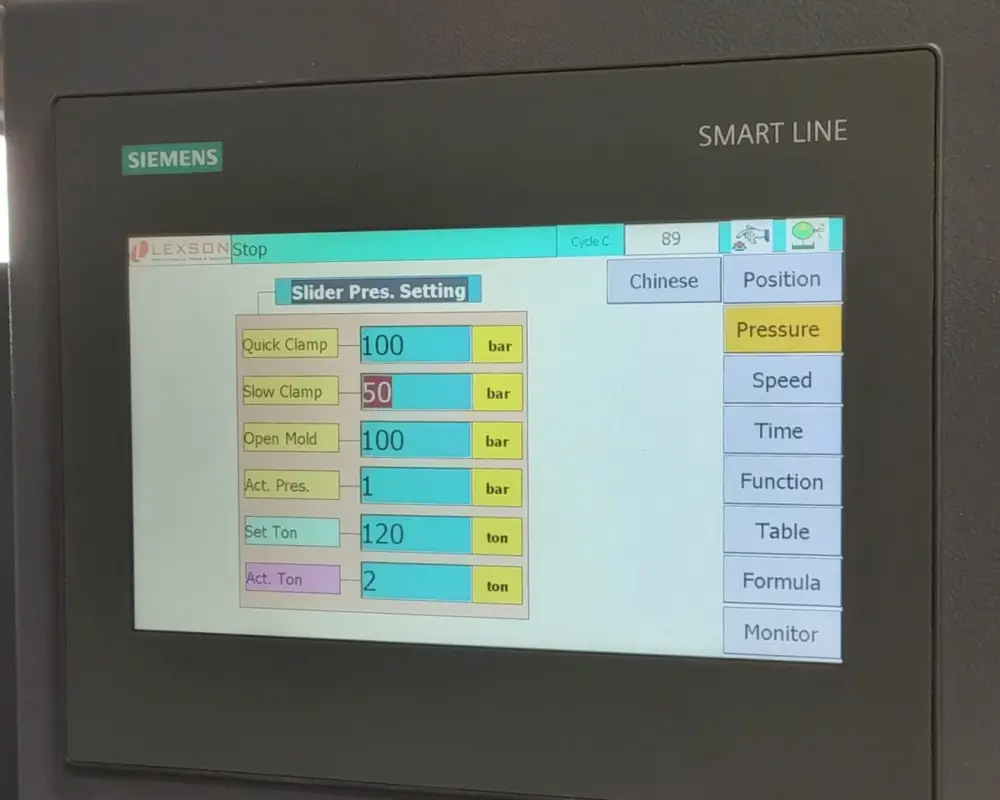

1 of 8Siemens Control Center:

Equipped with Siemens touch panels and PLCs for a reliable, comprehensive control experience.

2 of 8Workbench:

A workbench with parallel precision of ±0.01mm, optionally equipped with T-slots, a middle ejector cylinder, a movable workbench, a heated workbench, and more.

3 of 8 Emergency Stop Button and Dual-hand Start Button 4 of 8Electrical Cabinet:

Mainly equipped with Schneider electric components from France. 5 of 8

Mainly equipped with Schneider electric components from France. 5 of 8

Large Hydraulic Oil Cooler:

The large oil cooler ensures stable operation of the machine and extends its service life.

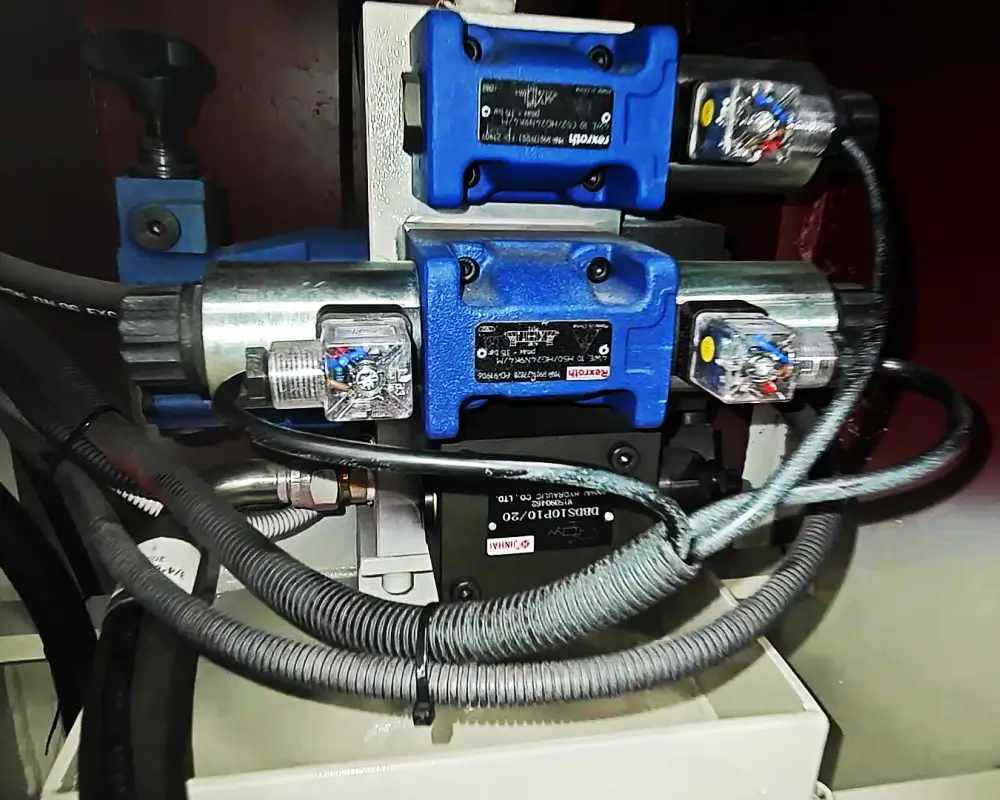

6 of 8Hydraulic Valve Group:

Equipped with modular hydraulic valve groups from Bosch Rexroth, Germany, for precise flow control, minimizing pipe connections and leakage.

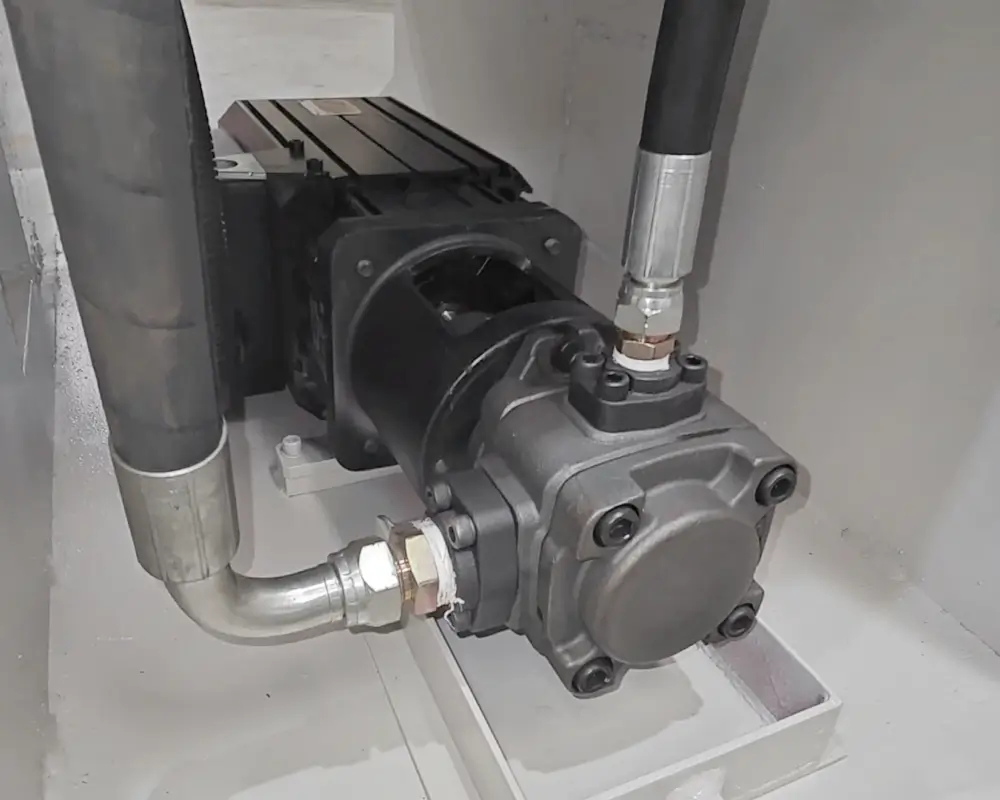

7 of 8Motor and Hydraulic Pump:

Equipped with the latest generation of Italian PHYSIS servo motors and German ECKERLE silent oil pumps, providing a top-tier power source for the C frame hydraulic press.

8 of 8Application Scenarios

Assembly and Press fitting

The stable and precise pressure provided by the C frame hydraulic press makes it ideal for fitting bearings, gears, wheel studs, etc., especially in applications requiring precise pressure control, thanks to its 0.01mm processing accuracy.

Stamping

The C frame hydraulic press can perform complex stamping operations, such as forming, shearing, and indenting.

Punching and Blanking

The open-frame design allows for easy placement and removal of materials, making it commonly used for punching and blanking on metal plates or parts, conveniently accommodating medium to long workpieces.

Trimming

The C frame hydraulic press is also commonly used for trimming, a relatively low-cost and efficient solution for trimming medium and small castings.

Forming

Frequently used for metal forming, especially in the field of medium and small metal compression molding, or converting flat metal into 3D parts.

Others

The C frame hydraulic press provides minimal stroke deflection, thus applications such as straightening, embossing, imprinting, riveting, etc., also frequently utilize it.

C-Frame Hydraulic Press Details

Machine Body

- Tonnage range from 10 tons to 800 tons (special quotes available for larger tonnages).

- Custom dimensions and speeds according to demand.

Hydraulic and Power System

- Equipped with the German Bosch Rexroth hydraulic valves, offering excellent stability, lower risk of oil leakage.

- Equipped with PHYSIS servo motors from Italy for noise reduction and energy savings of over 50%, ensuring higher accuracy.

- Equipped with the Chinese INOVANCE servo drive, providing accurate control and drive, faster response, higher efficiency.

- Equipped with ECKERLE hydraulic pumps from Germany for top-tier hydraulic oil flow control performance and quieter operation.

Control Panel and Monitoring Sensors

- Equipped with the German SIEMENS or Taiwanese WEINTEK smart touch screen, top-level control system experience, and comprehensive monitoring.

- Equipped with GIVI linear grating rulers from Italy, with accuracy up to ±0.005mm.

- Equipped with the Italian GEFRAN pressure sensor.

- Equipped with alarms for oil temperature, filter blockage, and other abnormalities.

- Equipped with liquid level control relay and liquid level observation window.

Workbench (Multiple Types Available)

- T-slot (optional).

- Movable workbench(optional).

- Heated workbench(optional).

- Middle ejector cylinder (optional).

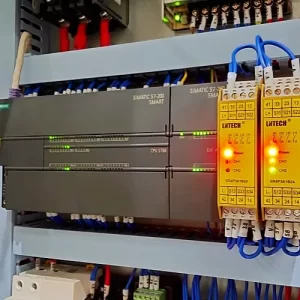

Electrical Components

- Equipped with German Siemens PLC, offering top-level control performance.

- Effectively prevents damage to electrical components from environmental factors such as dust, moisture, and extreme temperatures.

- Emergency stop circuit, using dual-channel monitored safety relays.

- Equipped with an electrical cabinet thermal management system.

FAQ

What is a C frame hydraulic press?

Are your machines custom or standard models?

What are the advantages of a C frame hydraulic press?

It offers fast speed, high precision, and is relatively cost-effective.

Christopher Adams –

It’s remarkably easy to maintain and has become an essential part of our production line.

David Wong –

I bought two Lexson C frame hydraulic presses in 2021, and repurchased them in 2024, finding that Chinese products offer a high cost-performance ratio.

Shane Robinson –

This press is quite a powerhouse despite its compact size.

Brian Lopez –

We bought this c frame hydraulic press primarily for its compact design, but have been pleasantly surprised by its power and durability.

Lucas Rossi –

After several months of using this c frame hydraulic press, I can confidently say it has significantly boosted our production efficiency.

Derek Wilson –

I purchased this C-frame hydraulic press for our manufacturing facility. It’s robust, efficient, and the customer service from the manufacturer has been outstanding whenever we had inquiries.

Nicholas Lewis –

This hydraulic press is exactly what we needed to streamline our metal fabrication processes.

Michael Young –

This hydraulic press applies even pressure and has helped us achieve precise results in our work.

Alexander Ford –

This press is everything we needed: powerful, precise, and durable.

Samuel Martin –

The C-frame design is a space saver and fits perfectly in our limited workspace.