What is a Press Brake?

Press brake is a crucial piece of machinery extensively utilized for precision bending and forming of sheet metal. It achieves bending by driving the movement of upper and lower dies through power systems like electric, hydraulic, pneumatic, mechanical systems. This versatile machine finds widespread application in metal processing industries such as automotive components manufacturing, construction, electronics, aerospace, and home furnishings, among others.

Press Brake Type

Mechanical Press Brake

The mechanical press brake is an ancient press brake type, originating in the early 20th century. The world’s first bending machine belonged to this category. Contemporary mechanical press brakes predominantly incorporate mechanical components such as flywheels, clutches, and transmission shafts. When the pedal is pressed, the motor drives the flywheel to rotate at high speed. The clutch transfers the flywheel’s kinetic energy to the transmission shaft, which then converts it into linear motion through internal mechanical mechanisms, thus driving the movement of the upper and lower dies to apply bending pressure to the sheet metal. This type is suitable for tasks with medium tonnage and relatively straightforward bending processes. The tonnage range typically lies between 20 to 1000 tons, often capable of exceeding twice or more of the rated pressure. However, there’s a growing trend of being replaced by hydraulic and CNC press brakes.

Advantages

- Cost-Effective: Due to lower costs, it generally offers a more budget-friendly option compared to other types with the same tonnage.

- Durability: Its relatively simple yet sturdy design results in higher durability. It requires fewer electronic and hydraulic components, leading to a longer lifespan.

- Lower Maintenance Costs: Thanks to its durability and lower component costs, maintenance expenses are generally lower.

- Simplified Operation: It doesn’t require programming, making it easier for those unfamiliar with CNC systems to operate.

Disadvantages

- Limited Automation: Lacking CNC systems, it’s restrictive when performing complex bending operations, relying heavily on manual expertise. Expanding automation is difficult.

- Limited Precision: Without CNC and crowning systems, the precision level is lower.

- Lower Production Efficiency: Slower work speed and lower automation contribute to reduced production efficiency.

- Limited Application Scenarios: Mostly suitable for scenarios with medium tonnage and moderate production volume.

- Lower Safety Level: Due to fewer electronic systems and sensors, its safety features are also less advanced. Additionally, during operation, the ram must complete the entire cycle, making it impossible to stop or change direction midway.

Hydraulic Press Brake

The hydraulic press brake is a press brake type based on Pascal’s principle and emerged in the 1970s. It utilizes a hydraulic system to generate high-pressure fluid, driving pistons to control the movement of upper and lower dies for metal bending. Depending on their operational method, they are primarily categorized as torsion-sync press brakes and electro-hydraulic press brakes. Hydraulic press brakes are suitable for medium to large tonnage applications, with a tonnage range typically between 50 to 3000 tons. Thanks to the precise control offered by hydraulic systems, they achieve higher accuracy compared to mechanical press brakes.

Advantages

- High Tonnage: Hydraulic systems transmit force through incompressible fluids, enabling them to deliver greater force compared to other transmission systems.

- Higher Precision: Hydraulic systems provide accurate control and can be equipped with a crowning system, resulting in enhanced machining precision.

- High Stability: Hydraulic systems ensure even force distribution due to the incompressibility of fluids, thereby ensuring a stable machining process.

- Wide Applicability: Capable of processing longer, thicker workpieces, and suitable for a vast majority of sheet metal materials.

Disadvantages

- Higher Purchase and Maintenance Costs: Hydraulic systems involve multiple hydraulic components and require regular inspection and maintenance, which increases both purchase and maintenance costs.

- High Energy Consumption: Hydraulic systems consume a considerable amount of energy.

- Risk of Oil Leakage: Prolonged usage of hydraulic systems can lead to the risk of oil leakage, necessitating regular inspections.

CNC Press Brake

CNC press brakes belong to a press brake type controlled by computer numerical control (CNC) systems and experienced rapid development in the late 20th century. The majority of them are equipped with hydraulic systems, essentially being an upgrade of hydraulic press brakes with the integration of CNC technology. Just like the hydraulic series, they are further classified into torsion-sync press brakes and electro-hydraulic press brakes. This type of press brake combines the advantages of both electric and hydraulic systems, often equipped with up to 12-axis backgauges, making them a popular and trending choice. The tonnage range generally falls between 50 to 4000 tons, accommodating a wide range of processing needs.

Further Reading

Differences Between Torsion-sync and Electro-hydraulic Press Brake

Advantages

- High Automation Level: Programmable for executing multiple processing sequences automatically, significantly reducing labor intensity.

- High Precision: Benefiting from precise control via CNC and hydraulic systems, maintaining accuracy typically within the range of 0.1 – 0.01mm.

- High Stability: The hydraulic system is considered one of the most stable choices.

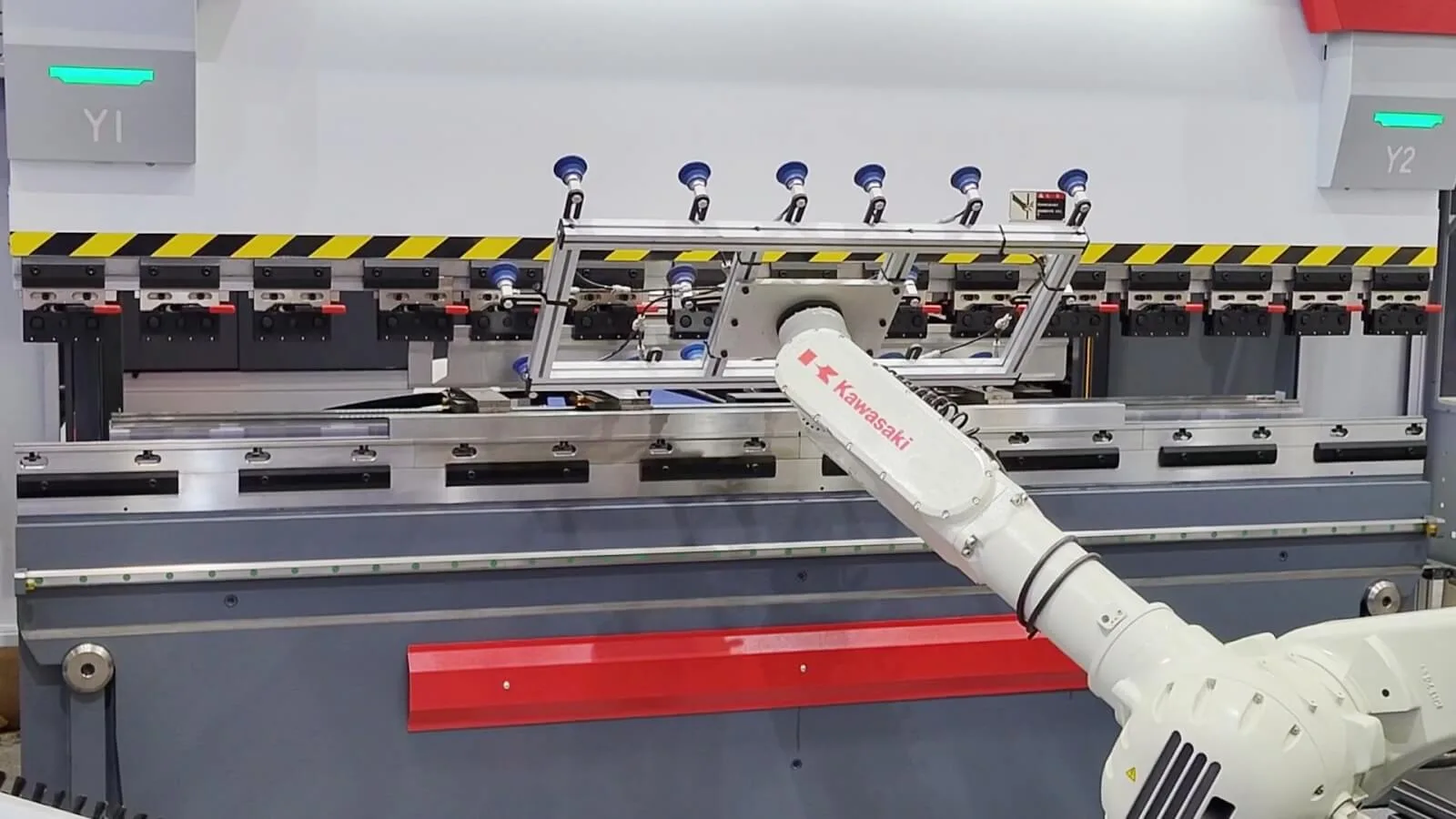

- Easy Automation Expansion: CNC systems facilitate straightforward integration of automation, allowing for the addition of automated extensions like robotic arms to increase efficiency and reduce labor costs.

- High Safety: Typically equipped with various sensors and safety components such as safety light curtains, mechanical safety sensors ensuring worker safety.

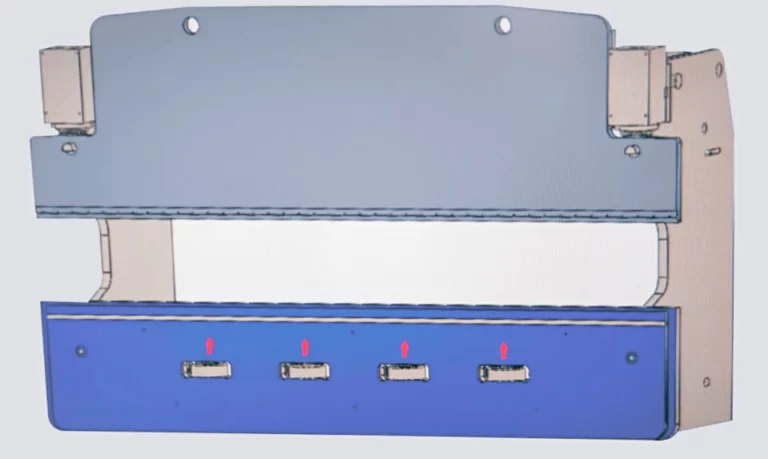

- Crowning System: Generally equipped with a crowning system, hydraulic or mechanical, significantly enhancing the precision of processing long and thick workpieces.

- Complex Workpiece Processing: Controlled by CNC systems with up to 12 axes, capable of easily handling intricate sheet metal fabrication.

- Broad Processing Range: Suitable for large, small, thin, and thick workpieces, capable of processing nearly all sheet metal materials.

- Energy-Efficient and Environmentally Friendly: An increasing number of CNC press brakes adopt servo motors, which can save up to 50% of electricity.

Disadvantages

- Higher Purchase and Maintenance Costs: The abundance of hydraulic and electronic components increases the cost compared to other press brake types. Regular inspection and replacement of parts can incur higher maintenance costs.

- Risk of Oil Leakage: Long-term usage of hydraulic systems carries the risk of oil leakage, necessitating regular inspections.

Electric Press Brake

This is a new press brake type driven by servo motors, originating from the late 20th century to the early 21st century. It operates quietly and efficiently, boasting fast and precise processing speeds. Electric press brakes are predominantly used for small to medium-sized sheet metal fabrication, with tonnage ranging from 5 to 600 tons.

Advantages

- Energy-Efficient and Environmentally Friendly, Low Noise: Equipped with servo motors, they consume power only during operation, resulting in energy efficiency. They also generate lower noise levels during operation.

- High Precision: The electric drive system, employing servo motors, achieves precise control, maintaining accuracy typically within the range of 0.1 – 0.01mm.

- Leak-Free: By avoiding hydraulic systems, the issue of oil leakage is eliminated.

- Fast Processing Speed: Processing speed is about 30% faster compared to hydraulic press brakes.

- Low Maintenance Costs: The purely electric drive system is simple, leading to lower maintenance costs.

Disadvantages

- Limited Tonnage: Due to the limitations of the electric drive system, they generally have a smaller processing tonnage.

- Limited Application Scenarios: Suited for precision processing of small to medium-sized components. They usually lack a crowning system and aren’t suitable for processing long or thick workpieces.

Pneumatic Press Brake

The pneumatic press brake is a press brake type controlled by a pneumatic system and emerged in the late 20th century. The primary power source is compressed air. Through pneumatic components such as cylinders and pneumatic valves, air pressure is transmitted to the upper and lower dies, completing the bending process of metal sheets. Its application range is very limited, with a pressure range typically ranging from 1 ton to around 100 tons. It is suitable for small-scale and lightweight sheet metal processing.

Advantages

- Cost-effective: This is a highly economical choice, offering a significant price advantage compared to other press brake types.

- Energy-Efficient and Environmentally Friendly: Using pneumatic power to drive the movement of the upper and lower dies, the pneumatic system is relatively simple, resulting in lower energy consumption.

- Simple Structure, Low Maintenance Costs: Its structure is straightforward and doesn’t require complex hydraulic or electric systems, leading to lower maintenance costs.

- Fast Processing Speed: Compared to other types of press brakes, it falls within the category of faster processing speeds.

Disadvantages

- Low Pressure: Due to the relatively simple pneumatic system, its tonnage range is usually smaller when compared to hydraulic press brakes.

- Limited Application Scenarios: It’s not suitable for processing long, thick, or hard sheet metals.

What Factors Should be Considered When Choosing a Press Brake?

In summary, when choosing the type of press brake, it’s essential to consider various factors beyond just tonnage. Factors such as precision, level of automation, lifespan, production capacity requirements, material thickness and type, bending length, and more should all be taken into account to ensure you select the press brake type that best suits your needs. Of course, budget is also a significant factor, requiring a balance between short-term budget constraints and long-term investment considerations.

Conclusion

Press brake technology continues to advance with innovations in control systems, automation, energy efficiency, and safety features. If your budget allows and for a long-term perspective, CNC press brakes are a superior investment. Additionally, electric press brakes are a cost-effective option. Velxun Machine offers both electro-hydraulic CNC press brakes and torsion-axis CNC press brakes, equipped with top-tier components in the industry, providing excellent value for money. These two machine models have been sold in over 40 countries worldwide. If you have any questions, please don’t hesitate to reach out to us for further consultation.