CNC Press Brake | Electro-Hydraulic Press Brake

WE67K Flagship Series Detail

With Velxun’s WE67K CNC press brake machine, you can expect superior performance, exceptional precision, and efficient production. This flagship machine embodies our commitment to engineering innovation and quality craftsmanship. Experience the advantages of our state-of-the-art technology and elevate your sheet metal bending capabilities to new heights.

Best-Selling Series

Oil-Resistant Design

Adopted servo motors

High Precision

Competitive Price

Best Components

Long Service Life

User-Friendly

Machine Video

WE67K CNC Press Brake Machine Front View

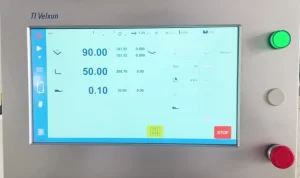

Cybelec 15 Controller:

Our CNC press brake is equipped with a user-friendly Swiss CNC system, featuring a 15-inch large screen and high-performance chips, making precise bending effortless.

1 of 7Pedal Switch:

High quality dual-pedal Pedal Switch with emergency stop function.

2 of 7Hydraulic Crowning:

Our CNC press brake machines are equipped with three to five hydraulic compensation cylinders, which are positioned below the worktable to achieve precise compensation.

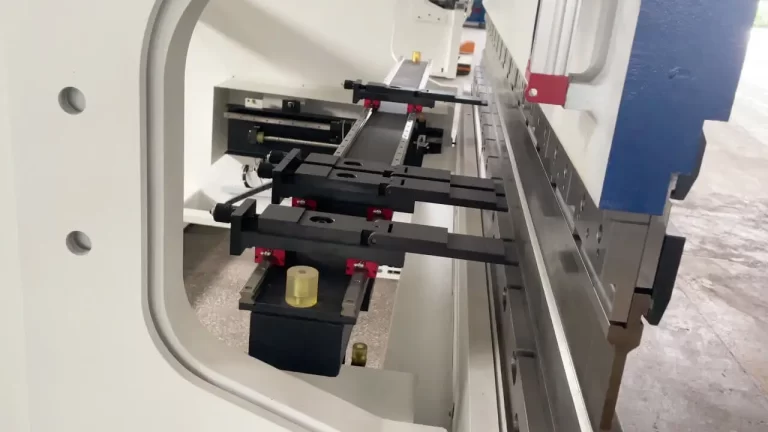

3 of 7Backgauge:

The X+R axes adopt Taiwan Hiwin backgauge, and optional Z1+Z2 axes are available.

4 of 7Fast Clamp:

One-key removal of the die, ensuring safety, speed, and durability.

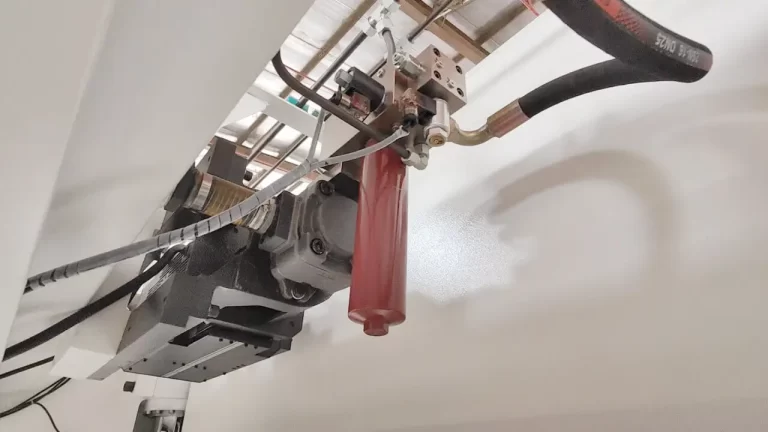

5 of 7Y1 Hydraulic Cylinder:

Our hydraulic cylinders undergo multiple anti-leakage oil treatments, and Italian GIVI high-precision optical linear scales are installed on both sides of the Y1 and Y2 axes, with an accuracy of up to ±0.005mm.

6 of 7Front Sliding Shelves:

A pair of front sliding racks are designed with adjustable height and a 180-degree rotation feature, providing flexibility and convenience in loading and unloading materials.

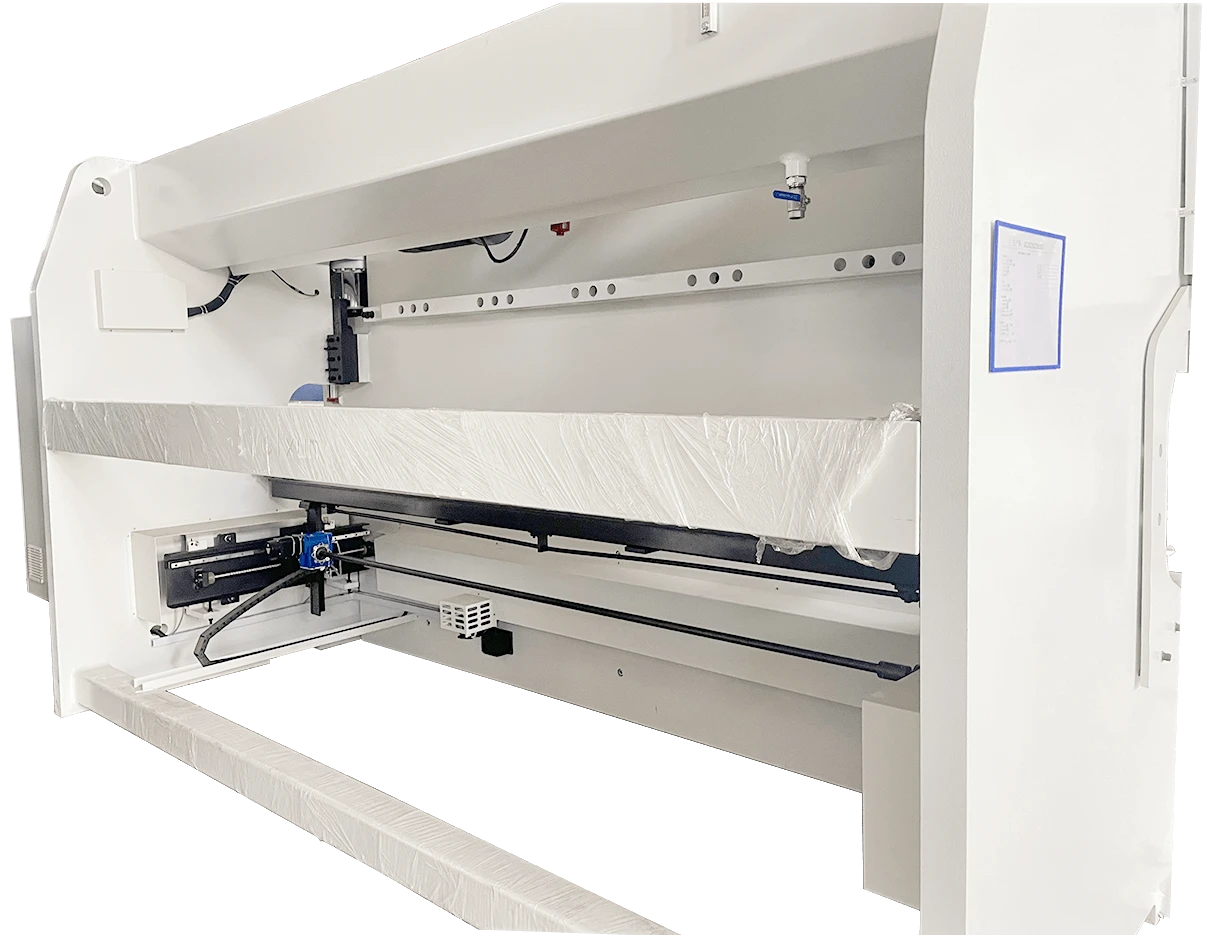

7 of 7WE67K CNC Press Brake Machine Back View

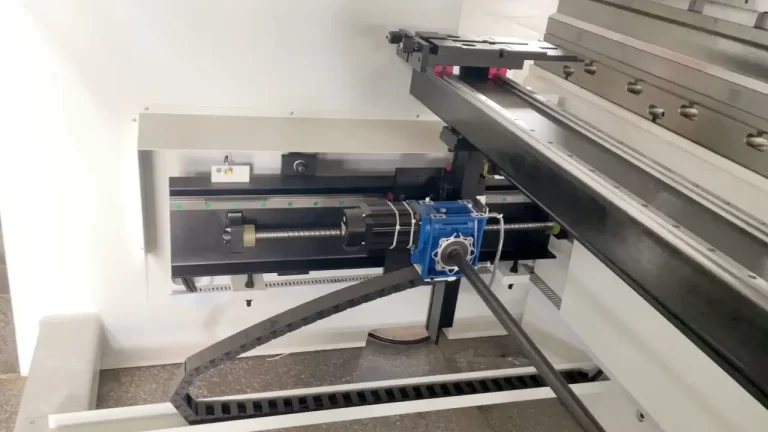

Motor:

Our press brake machine is equipped with motors from either VEICHI in China or Siemens in Germany, with VEICHI servo motors significantly reducing energy consumption and noise.

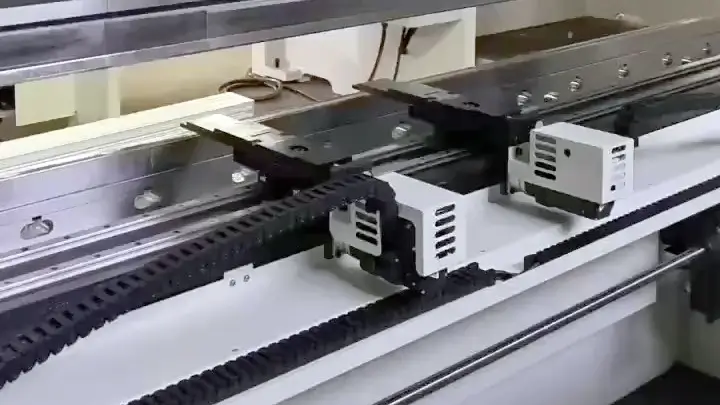

1 of 7Backgauge Servo Motor

2 of 7Ball screw & linear guide:

Equipped with Taiwan HIWIN ball screw, linear guide, and polished rod structure.

3 of 7Y2 Hydraulic Cylinder

4 of 7Oil pump & hydraulic valve:

Our CNC press brake machine is equipped with hydraulic pumps from Sunny, and hydraulic valves from Bosch Rexroth.

5 of 7Electrics:

Our press brake is equipped with Schneider electrical components from France. Schneider Electric is known for producing high-quality and reliable electrical components.

6 of 7Dual Linear Guide:

Our CNC press brake is equipped with high-speed and stable dual linear guides from Taiwan HIWIN.

7 of 7Machine Features

- Core of our product lineup.

- Low noise and low energy consumption.

- High level of automation.

- 63 to 1600 tons of bending force.

- 4+1 to 6+1 axis.

- Hydraulic deflection compensation.

- High-strength welding, carbon tool steel worktable.

- Advanced servo motors.

- User-friendly and simple operator interface.

- The workbench length ranges from 2500mm to 9000mm.

- Large daylight opening, long stroke.

- High-end imported components.

- Low maintenance cost.

Software

- Full-screen touch interface, user-friendly operation.

- Supports offline programming. Capable of being integrated with the MES system.

- Supports importing DXF/DWG, IGES, STEP, SAT and X_T files.

Expandable

- Sheet bending follower.

- Robotic Arm.

- Tandem press brake configurations.

Enhanced Durability

- Adopting SKF seals from Sweden, hydraulic cylinder pistons are heat-treated and then chrome-plated.

- Robust body structure with high-quality mild steel.

- Machine tool structure shot blasting.

- Before Packing, the machine tool undergoes a 72-hour testing period to ensure that all equipment meets 100% quality standards.

Services

- Remote control, management, diagnostics.

- Free training sessions are conducted at our factory in Dongguan, China.

- Expert guidance by well-qualified and experienced engineers for the most suitable machine selection.

- We provide overseas maintenance support.

Press Brake Machine Structure

Brand-new industry design, our high-strength welding machine tool structure consists of two C-Frames that form the sides of the CNC press brake machine.

Totally European design. The frame is constructed with integral welding, ensuring smooth operation with top-notch welding techniques. With a large throat, long stroke, and narrow table, there is plenty of space to accommodate intricate bending sequences.

Our CNC press brake features a worktable made of carbon tool steel, resulting in minimal wear and long service life. Adopts a three-plate structure and hydraulic deflection compensation system.

Shot blasting, high-strength welding, good rigidity.

Cybelec 15 CNC Control System

Originating from Switzerland, this renowned CNC press brake machine system is known for its high precision positioning control and powerful programming capabilities. It is currently considered the most user-friendly and easy-to-learn CNC system for press brakes.

- Standard with 4+1 axes, upgradable to 6+1 axes (Y1 + Y2 + X + R + Z1 + Z2 axes), with the “1” referring to the compensation axis.

- Utilizing high-performance chips from TI (USA Texas Instruments).

- Pressure, hydraulic crowning, and pump speed management.

- Utilizing cutting-edge algorithms for precise control of closed and open-loop proportional valves.

- Remote control, management, diagnostics, and machine updates.

- Automatic straightness and angle correction.

- Easy programming for efficient mass-production with multi-step bending.

- In addition, our CNC press brake also offers the option to choose DELEM’s CNC system.

Large 15” touchscreen. High-performance chips from TI (Texas Instruments).

Main Motor

Our CNC press brake is equipped with a high-end servo motor from VEICHI, a leading Chinese brand, which reduces noise by 30% and power consumption by over 50% compared to conventional motors. It also offers outstanding performance and stability.

In addition, our CNC press brake also provides the option to select motors from renowned brands such as Siemens from Germany or Dongguan motors from China. These motors are known for their superior quality, performance, and reliability.

Energy-saving, and low noise. Stable and durable performance.

CNC Backgauge System

CNC press brake machine of Velxun is equipped with a high-speed backgauge from Taiwan Hiwin, adopts precision recirculating ball screw, and a linear guide rail which reduces X and R axis positioning error to less than 0.01 mm. It utilizes advanced sensors and measurement technologies to ensure precise positioning and detect any deviations or errors.

- Suitable for workpieces that require precise bending with multiple steps.

- Standard configuration includes X and R axes, Expandable to Z1 and Z2 axes.

- The backgauge adopts a tank-type structure, providing sufficient mechanical strength and rigidity.

- The backgauge is driven by a servo motor.

- Inching, single cycle, and auto run.

- positioning accuracy ± 0.01 mm.

High-speed and high repeatability precision.

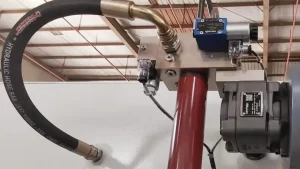

Hydraulic Unit

Velxun’s CNC press brake machine adopts a close loop electro-hydraulic synchronized servo-control system and latest high-frequency responding hydraulic control technology.

Our hydraulic oil pump is sourced from Sunny in the USA, and the hydraulic valve is sourced from Bosch Rexroth in Germany.

Adopts an integrated hydraulic control system, effectively addressing oil leakage issues. The hydraulic system is equipped with overload overflow protection.

The hydraulic cylinder is equipped with high-quality sealing rings from SKF Switzerland, and the piston rod of the cylinder is chrome-plated after undergoing heat treatment. Its structural design and material selection provide excellent durability and strong load-bearing capacity, enabling it to operate reliably under high pressure.

latest high-frequency responding hydraulic control technology.

Hydraulic Crowning | Mechanical Crowning

Velxun’s CNC press brake machine is equipped with 3 to 5 hydraulic compensation cylinders below the worktable, depending on the length of the machine body.

User-friendly operation with consistent and precise bends, equipped with the ability to automatically calculate deflection compensation. Minimal technical expertise is required for press brake operators, to ensure stability and high precision.

Our CNC press brake offers the option of choosing mechanical crowning.

High precision hydraulic crowning.

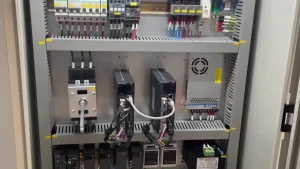

Electrical Parts

The CNC press brake machine of Velxun adopts Schneider electrical components, which provide excellent anti-interference capabilities and consistent electrical performance, ensuring longevity and durability in demanding press brake applications.

Electrical components conform to international standards, ensuring safety and reliability.

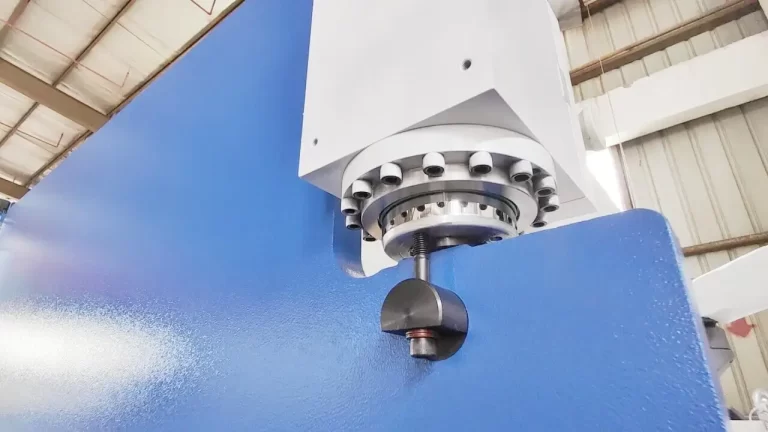

Manual Upper Tool Clamping

Our CNC press brake’s quick clamping system is designed to easily accommodate workpieces of various sizes and shapes.

- Safe and fast tool change.

- Constructed with high-quality materials and robust engineering, it delivers durability and longevity.

- Simple push-button loading, one-key release fast clamp.

- Its reliable clamping mechanism securely holds the workpiece in place, ensuring accurate positioning during the bending process.

One-key release clamp.

Other Components

Velxun’s CNC press brake utilizes components from top international brands for 90% of its parts.

- The optical linear scale adopts GIVI from Italy, with an accuracy of ±0.005mm.

- The Servo valve and proportional valve are sourced from Bosch Rexroth in Germany.

- Pedal switch with emergency stop function.

All components are equipped with top-of-the-line specifications.

FAQ

What type of press brake is this?

This machine can be called a "CNC press brake" and is also referred to as a "CNC hydraulic press brake". Based on its power system and control method, it can also be called a "CNC electro hydraulic press brake". Velxun's WE67K series combines the advantages of electric press brakes and hydraulic press brakes.

What is a CNC electro hydraulic press brake machine?

CNC electro hydraulic press brake is a classification of hydraulic press brake that is based on the control system used and operating mode. it represents a trend in the machine industry. It combines the precision and reliability of hydraulic systems with the efficiency and accuracy of electronic control. Compared to other types of press brakes, the CNC electric hydraulic press brake offers advantages such as higher control precision, greater flexibility in adjustment, lower energy consumption, and higher automation level.

What is the positioning of this model among your CNC press brake machine?

This model of machine is positioned as a flagship model among all our machine types, suitable for medium to large-scale production, which has a very wide range of applications. It is the best-selling model among all our press brake machine types, which catering to the diverse needs of professionals in the press brake industry.

How long is the training period for beginners to use this machine?

The machine's control system is user-friendly and easy to learn. It typically takes only 1 day of training to become familiar with the basic operations of the machine, while becoming proficient usually requires 2-3 days of practice.

What is the warranty period?

The machine and its components have a one-year warranty, and we also provide additional options for extended warranty periods.

Leandro Prescott –

High production speed, strong safety features, I am very satisfied.

Kirs Paul –

We’ve put Velxun’s CNC press brake machine through rigorous tasks, and it has surpassed our expectations. It withstands heavy usage and continues to operate reliably, minimizing downtime. It’s built to last and can handle the toughest metal sheet materials.

Jeffrey Murphy –

Excellent after-sales service, assisting with any concerns or issues promptly.

Patrick Sullivan –

The machine’s high-speed operation ensures rapid turnaround for time-sensitive projects. Easy maintenance and accessibility to components simplify routine upkeep and repairs.

Charles Griffin –

Velxun’s CNC hydraulic press brake machine offers excellent cost-effectiveness.

Eric Thompson –

Velxun’s CNC press brake machine adopts energy-efficient components and advanced power management systems to minimize energy consumption.

Matthew Cox –

Compatibility with CAD/CAM software simplifies the transfer of designs for efficient programming.

Stephen Hayes –

Easy to learn and operate, reducing training time and increasing overall efficiency.

James Mitchell –

The CNC hydraulic press brake machine’s noise reduction features create a quieter working environment for operators.

Michael Clark –

As someone with experience in metal sheet work, I was keen to find a reliable press brake to assist me with my projects. After thorough research, I decided to invest in a machine from Velxun. It is a powerful mechanical device that can easily bend and form metal sheets into any desired shape. I highly recommend this press brake to metal fabrication process.

David Wright –

The machine has a highly aesthetic appearance and is quiet, energy-efficient, and power-saving.

Isaac Clark –

The user-friendly interface of this CNC press brake machine makes it incredibly easy to operate, which programming the machine is intuitive.

William Anderson –

We have been using this CNC press brake machine for a considerable time, and it has proven to be highly durable.

Peter Smith –

Accommodates various projects seamlessly, ensuring flexibility in metal sheet processing.

Alan Bell –

Velxun’s machine is our main model for machining complex workpieces.

Gary Wood –

Allows for customization, easily adjusts bending parameters for diverse project requirements.

Alan Chan –

Excellent after-sales support, prompt assistance and technical guidance whenever needed.

Terry Reed –

Exceptional precision! This cnc press brake machine consistently delivers accurate bends with minimal deviation.

Keith Cox –

I’ve used other hydraulic press brake machine, but none can match the precision of this one. It’s perfect for intricate and delicate sheet metal fabrication.

Mark Johnson –

Velxun’s CNC press brake machine impresses with its speed and cycle times, improving productivity in metal sheet processing.

Paul Anderson –

This is a machine with excellent cost-performance ratio.

Johnson Wong –

Highly efficient CNC hydraulic press brake machine, reduces production time and boosts overall efficiency.

Wayne Simpson –

The ability to fine-tune the bending parameters on this hydraulic press brake machine is fantastic. It feels sturdy and well-engineered, designed to withstand the demands of heavy-duty sheet metal fabrication.

Steven Palmer –

Great customer service. They answer your questions all the time.

Robert Collins –

Velxun’s CNC press brake has been a reliable workhorse in our metalworking shop, allowing me to produce complex sheet metal components with ease. This machine is a game-changer for any metal fabricator.

Joseph Mitchell –

During my second purchase of the machine, I noticed an increase in price. The manufacturer informed me that they had implemented iterative upgrades to the machine.

Christopher Roberts –

The machine has been a solid performer in my workshop, and I’ve been able to achieve consistent results with various materials. The build quality is excellent, and I haven’t encountered any major issues so far. I would recommend it for medium-sized projects.

Brandon Young –

I have been using the CNC press brake machine for several months now, and I must say that I am extremely impressed with its precision and accuracy. It handles large sheet metal sizes with ease, which improved our productivity and overall efficiency. Overall, I am delighted with both the machine and the support we have received.

Daniel Martin –

Velxun’s CNC hydraulic press brake has been a workhorse in our fabrication shop.

Tyler Wilson –

Fairly satisfactory.

Benjamin Roberts –

After comparing eight manufacturers, I recommend all metal sheet processing companies to purchase this CNC press brake due to its exceptional cost-performance ratio.

Samuel Murphy –

We are a startup company, and Velxun machines have been incredibly helpful to us. Their service and support have been exceptional, paying attention to every detail.

Mia Reed –

Velxun is our long-term partner.

James Wilson –

The delivery was delayed due to the COVID-19 pandemic, but the machine is still satisfactory.

Noah Walker –

A versatile machine that can handle a wide range of materials and thicknesses.

Ethan Thompson –

Investing in the CNC press brake has significantly reduced our production cycle times. Highly recommended!

Jackson Campbell –

The electro-hydraulic press brake is indeed much more efficient than traditional.

Amelia Foster –

Perfect, I love Velxun.

Emily Thompson –

The CNC hydraulic press brake machine we purchased has exceeded our expectations. We have experienced minimal downtime, resulting in increased production output and cost savings.

Grace Young –

This is our 3th machine purchase, and Velxun’s machines have effectively met our production expansion needs. Every machine is consistently reliable and stable.

James Robinson –

I am highly impressed with the CNC press brake’s performance. It consistently delivers precise and accurate bends, meeting the strictest tolerances.