Press Brake Manufacturer

Velxun is a leading press brake manufacturer in China. We offer two machine models: CNC press brake and NC hydraulic press brake based on the control system and power source. These machines have undergone more than thirty years of iterative refinement, making them exceptionally mature in their design and performance. It is worth mentioning that the very first press brake we exported has been working continuously for over thirty years without major faults.

Press Brake FAQ

Why choose your machines?

First and foremost, we are an integrated source factory that combines research and development, production, and sales. Our well-controlled cost management ensures competitive factory prices. Additionally, with over 30 years of industry experience, our machines undergo continuous iteration and upgrades to ensure leading performance in the industry. We prioritize the reliability and durability of our press brake machines. They are built with high-quality materials and undergo rigorous testing to ensure long-lasting performance, even in demanding production environments. In terms of service, we provide 7x24 one-on-one support. We are committed to continuously improving the quality of our machines and striving to exceed our customers' expectations.

What types of press brake do you have?

We mainly have two models, namely CNC press brake and NC hydraulic press brake.

What are the differences between these types of press brakes?

Our CNC press brake represents our cutting-edge technology and offers comprehensive coverage for various types of sheet metal processing. It excels in precision and reliability, making it our flagship and best-selling model. On the other hand, the NC hydraulic press brake is the optimal choice for cost-sensitive applications. It caters to the majority of sheet metal processing scenarios while maintaining an absolute competitive edge in terms of price in the market. It is the go-to option for small and medium-sized sheet metal processing.

What is the pricing for these machines?

Our machine prices vary depending on the specific accessory choices. We can provide the best value for money in the industry. If you have any questions, please contact us, and our professional sales engineers will provide you with a detailed quotation.

What type of materials can they handle?

These press brakes are capable of handling various types of metal sheets, including iron, copper, stainless steel, aluminum, and more. With their versatile design and adjustable parameters, they provide the flexibility to accommodate a wide range of metal materials for bending operations.

What is the warranty period?

All our series of press brakes come with a one-year warranty. Additionally, we offer extended warranty options for an extended coverage period. For machines that are no longer under warranty, we provide fee-based global repair services worldwide.

How to maintain a press brake?

- For newly purchased press brakes, it is recommended to change the oil once within the first month of purchase. Afterward, it is advised to change the oil and clean the oil tank once a year.

- Clean the machine regularly, removing debris, dust, and residue from critical components such as the bending tools, backgauge, and hydraulic system.

- The hydraulic cylinder seals should be replaced every four years.

- The hydraulic oil temperature of the press brake system should be maintained between 35-60 degrees Celsius and should not exceed 70 degrees Celsius.

- The hydraulic oil filter should be replaced or thoroughly cleaned every time the oil is changed.

- After one month of usage, inspect the press brake for any abnormal deformations or bends in the oil pipes. If any irregularities are found, they should be replaced.

- Electrical System Maintenance: Inspect the electrical system regularly for any loose connections, worn-out cables, or damaged components.

- Regular online updates of the CNC system for the press brake ensure that your machine operates with the latest features.

Why Choose Us?

Advanced Technology

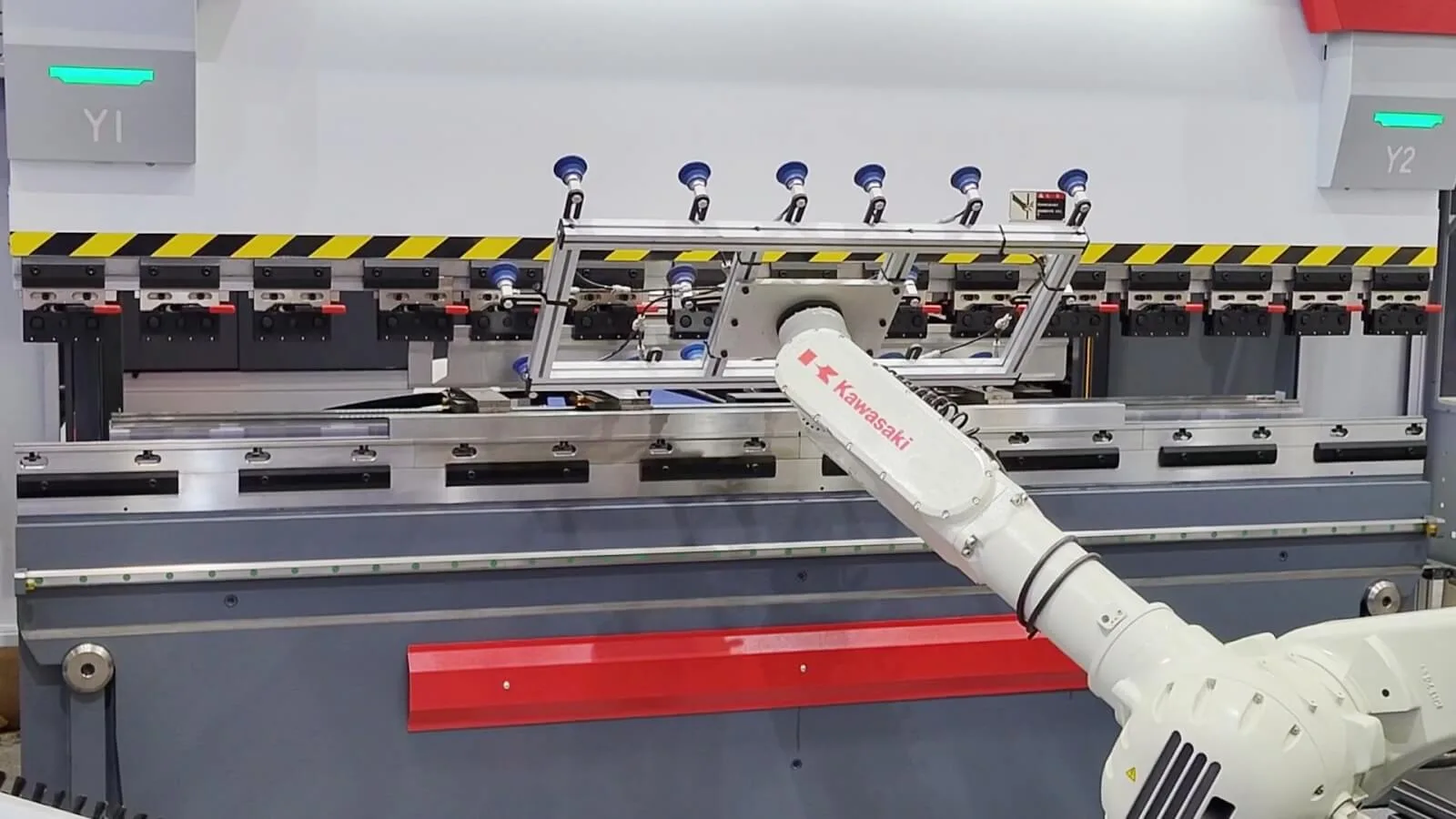

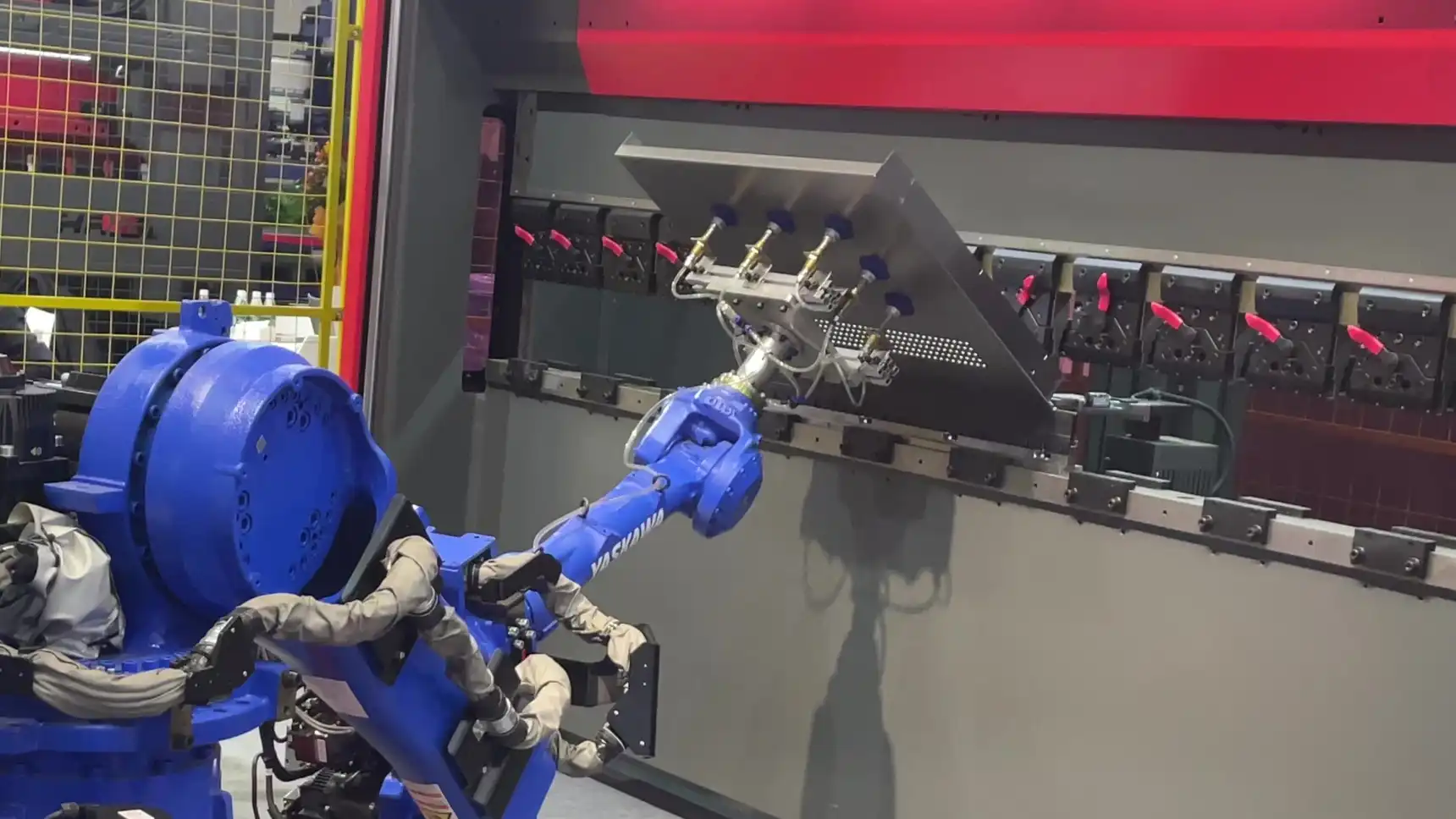

Our machines excel in all technical specifications, delivering exceptional bending performance, consistent results, and improved productivity, positioning us at the forefront of the industry. We stay updated with the latest industry advancements to provide you with state-of-the-art solutions.

High Quality

Our press brake is built with robust construction and high-quality components to ensure durability and longevity, capable of operating reliably in various work environments and providing consistent bending results.

Comprehensive Service

Our knowledgeable team of professionals is here to assist you from the initial stages of your inquiry. Whether you have inquiries about machine settings, troubleshooting, or maintenance, our experts are just a phone call or email away.

Competitive Pricing

We aim to make our press brakes accessible to businesses of all sizes, ensuring that you get the best return on your investment while maintaining profitability in your operations.

Worry-free after-sales

We offer remote assistance for prompt technical issue resolution and maintain a stock of genuine spare parts to minimize production disruptions. If remote assistance is insufficient, we provide global on-site repair services, regardless of your location.

Press Brake Blog

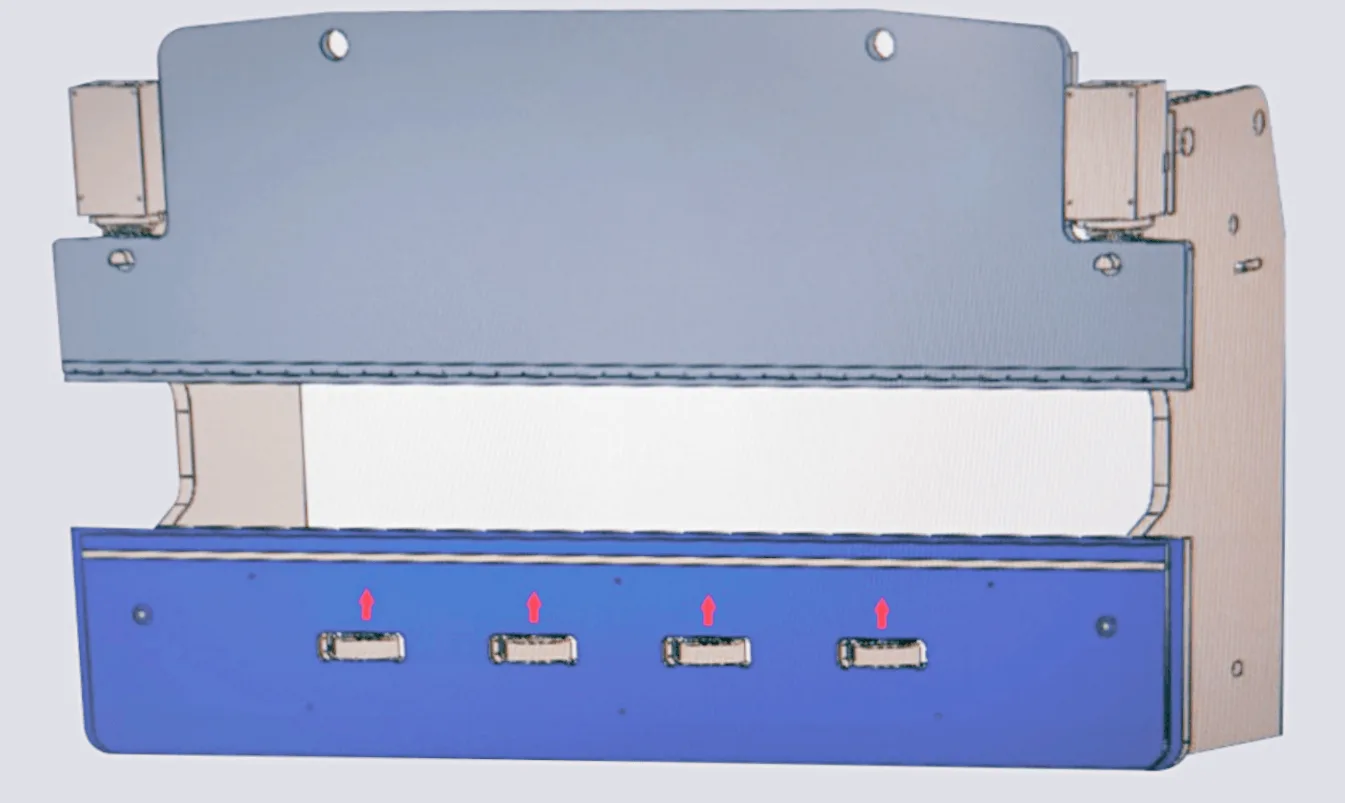

What is Press Brake Crowning? Hydraulic vs. Mechanical Crowning (5 Major Differences)

Press Brake Types: How to Choose the Right Press Brake?

9 Differences Between NC and CNC Press Brake

Our Clients Say

share: