What is The Hydraulic Press Structure?

The hydraulic press structure refers to the main bed frame of the machine, providing the foundation for the hydraulic press and supporting the applied pressure. It is a crucial component of the machine, ensuring overall rigidity and strength. Hydraulic press structures are primarily categorized into four types: 4-post, 2-post, H-frame, and C-frame. Each of them has its own characteristics, offering different choices to customers.

What are the different types of hydraulic press structures?

4-Post Hydraulic Press

The 4-post hydraulic press refers to a hydraulic press design that incorporates four vertical columns between the upper crossbeam, lower crossbeam, and the ram. These columns provide support and guidance for the ram and bed. Due to its larger working surface area and more uniform force distribution, it is suitable for various sizes of workpieces, making it one of the most popular hydraulic press structures. 4-post hydraulic presses can have very high tonnages, even exceeding ten of thousand of tons. It offers the flexibility of loading workpieces from four sides. Thanks to its use of a 4-post vertical support structure, it provides a more robust and stable construction with higher parallelism. The most common configuration is the three-beam 4-post design.

Common Applications of 4-Post Frame

Trimming, Hot pressing, Deep drawing, Punching, Compression forming, Stamping, Metal forming, Bending, and more.

Recommended Machine

Trimming press, Heated platen press, Die cutting press, Compression molding press, Deep drawing press.

4-Post Frame Features

- High tonnage

- High precision

- Wide application range

- Excellent stability and even load distribution

- Large working area, but a significant footprint

- High flexibility, easy loading and unloading of workpieces

- Requires more maintenance

- High customizability

2-Post Hydraulic Press

The 2-post hydraulic press is a hydraulic press with two vertical pillars set up between the upper beam, lower beam, and the ram. These columns provide support and guidance for the ram and bed structure. It has a relatively smaller footprint compared to 4-post hydraulic press, and they feature a simple and straightforward design with fewer components. They are suitable for medium to small-sized workpieces and applications that require moderate pressure. Due to having only two pillars, the working table area is smaller compared to 4-post hydraulic presses, and it offers less stability. It is a more cost-effective choice when compared to 4-post hydraulic presses.

Common Applications of 2-Post Frame

Hot Pressing, Press fitting, Riveting, Coining, Assembly, and more.

2-Post Frame Features

- Medium tonnage

- Easy to operate

- Compact design with a smaller footprint

- Cost-effective and budget-friendly

- Low maintenance requirements

- Shorter manufacturing lead times

- Limited application scope, suitable for medium-sized workpieces

C-Frame Hydraulic Press

The C-Frame hydraulic press is so named because its machine frame resembles the letter “C.” It typically consists of a C-shaped steel frame, a ram, an upper platen, and a lower platen. It offers three open sides in the workspace, providing good flexibility. Due to its structural characteristics, C-Frame hydraulic presses are better suited for medium to low-tonnage processing applications. They also offer high processing precision and are a cost-effective choice. However, due to tonnage limitations, their applicable scenarios are relatively limited.

Common Applications of C-Frame

Punching, Straightening, Press fitting, Assembly, Riveting, and more.

Recommended Machine

Straightening press, Assembly press, Riveting press.

C-Frame Features

- Low to medium tonnage

- Easy to operate

- Compact and space-saving design

- Limited application scope

- Smaller footprint, but lower space utilization

- High precision

- Easy installation and debugging

- Cost-effective

- Three-sided access, flexible operation

- Quick machine manufacturing time

- Minimal maintenance requirements

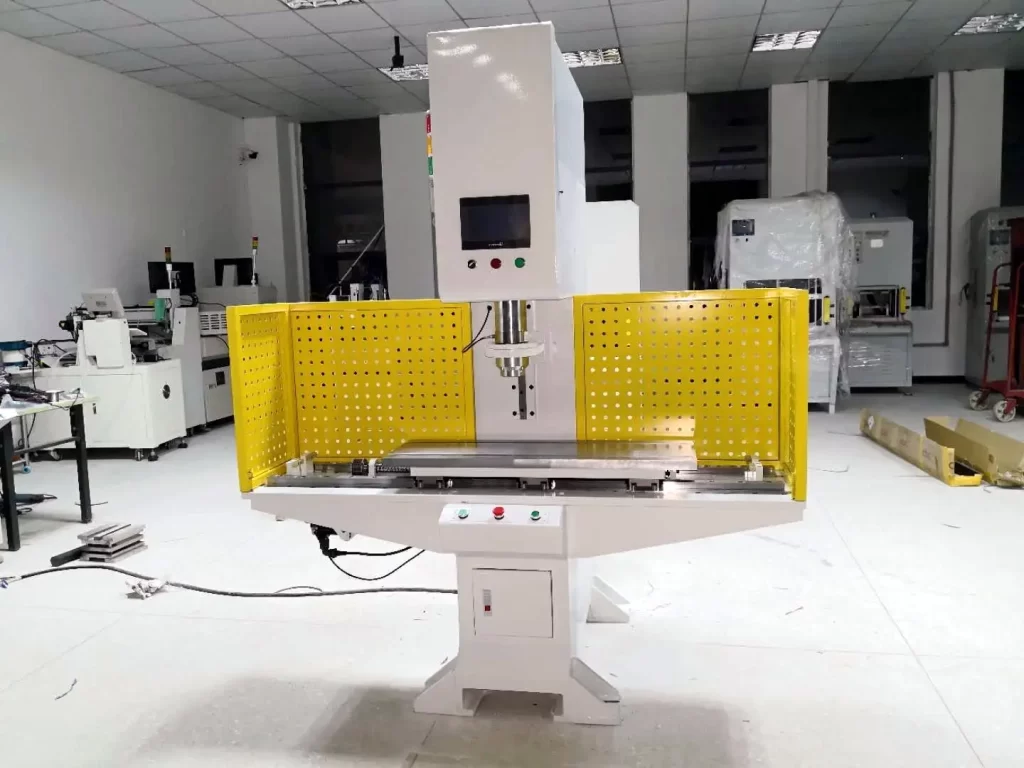

H-Frame Hydraulic Press

The H-Frame hydraulic press, also known as a straight-side hydraulic press, is typically composed of a rectangular frame and a horizontal crossbeam, giving it the appearance of the uppercase letter “H”. Its “H” frame provides stability and support from all four sides of the workspace, making it a widely used type of hydraulic press. The machine body is usually designed as an integrated unit, offering two open sides in the work area. It has a short stroke length and higher tonnage capacity. Gib-guided hydraulic presses often adopt this structural design, it is one of the most stable and precise hydraulic press structures.

Common Applications of H-Frame

Deep Drawing, Straightening, Compression forming, Punching, Coining, Stamping, Metal forming, and more.

Recommended Machine

Stamping press, Deep drawing press, Forging Press, Punching blanking press.

H-Frame Features

- High precision

- High tonnage

- Short stroke length

- Wide application range

- Smaller footprint with efficient space utilization

- Compact design

- Large working area

- Durable with low maintenance requirements

- Highly customizable

Conclusion

When choosing your hydraulic press, consider factors such as workpiece size, weight, tonnage, stroke length, and floor space. Different frame types are suitable for different applications. 4-post and H-frame hydraulic presses are among the most popular and versatile options, while C-frame and 2-post hydraulic presses are cost-effective choices for precision work on small to medium-sized workpieces.

About Us

Lexson is a professional custom hydraulic press manufacturer under Velxun Machine. We offer custom services for C-frame hydraulic presses, H-frame hydraulic presses, 4-post hydraulic presses, and 2-post hydraulic presses. Regardless of the size, tonnage, or application requirements of your machine, we can provide comprehensive solutions. Feel free to reach out to us for inquiries and assistance.