Hydraulic Press Brake | Torsion Bar Press Brake

WC67K Econom Series

Our NC hydraulic press brake machine offers exceptional accuracy, a user-friendly interface, and competitive pricing, making it a reliable solution for your bending needs. Whether you are working with thin or thick materials, this machine guarantees exceptional performance and efficiency. By state-of-the-art technology, our NC hydraulic Press Brake stands out as an economical choice for professionals in the industry.

Economic Series

Small to Medium Production

Sturdy And Stable Main Frame

Easy Operation

Significant discounts

Premium Components

Support Multi-Step Programming

Excellent Value for Money

Youtube Video

WC67K NC Hydraulic Press Brake Various Parts

Cybelec 8 Control System:

The Cybelec Cybtouch 8 control system from Switzerland, specifically developed for torsion-sync press brakes, offers low learning costs and is a classic CNC system that ensures smooth and efficient production.

1 of 7Foot Switch:

Foot switch with emergency stop function.

2 of 7 BackgaugeBackgauge:

The backgauge of the NC hydraulic press brake is available in two versions: X-axis or X+R-axis. The level of precision places it among the high standards in the category of torsion-sync press brakes.

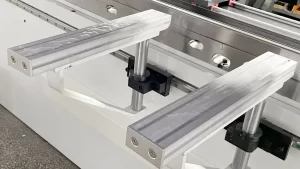

3 of 7Easy Clamp:

The easy clamping has the ability to quickly adapt to different sizes and shapes of workpieces.

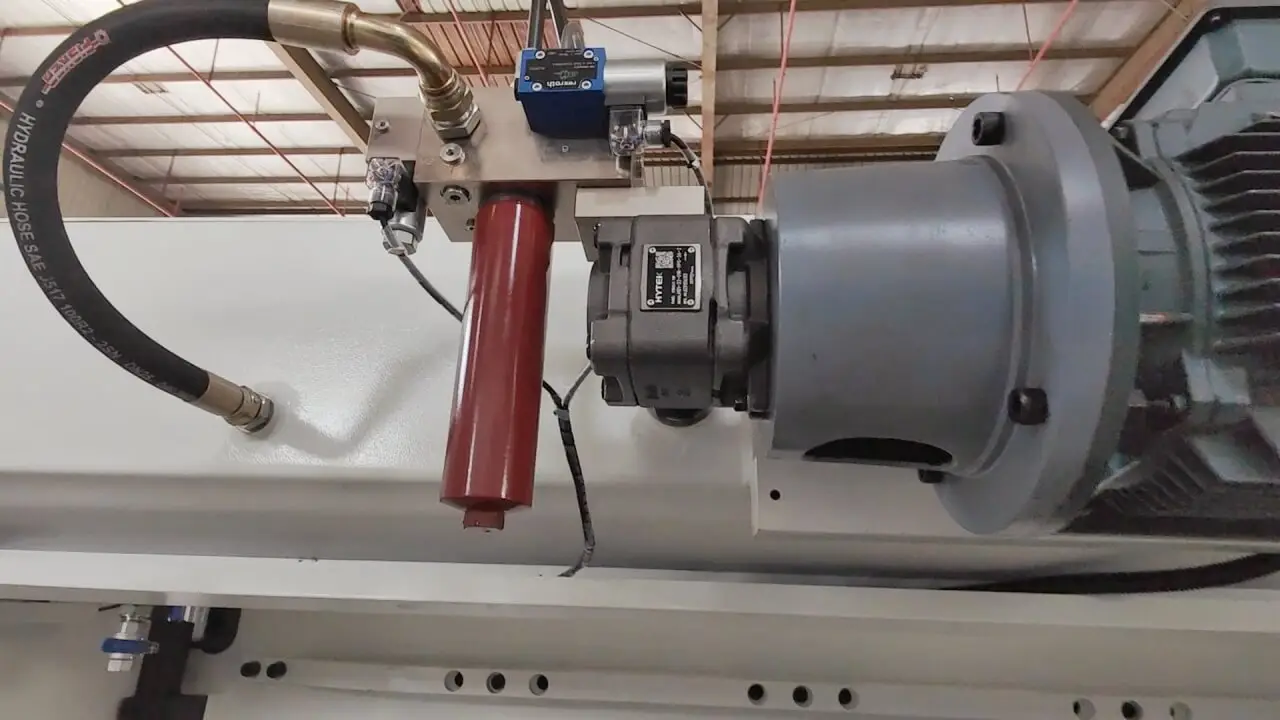

4 of 7Hydraulic Oil Cylinder:

Our hydraulic oil cylinder utilizes high-quality seals and materials, ensuring an extended lifespan. It has been designed with safety in mind, equipped with safety valves and protective devices to ensure safe shutdown in case of unexpected situations.

5 of 7Front Shelves:

A pair of front sliding shelves, with a maximum weight capacity of 120kg, guaranteeing ergonomic use and ease of handling for workpieces.

6 of 7 Hydraulic PowerHydraulic Power:

Minimize oil leakage risk with an integrated hydraulic system and fewer pipelines.

7 of 7Why Choose Us

- Cost-effective series

- Achieving High Precision in Sheet Metal Processing

- Available with either X+Y+R axes or X+Y axes

- 35 to 400 tons of bending force

- Robust and durable machine structure

- Compact footprint, maximum output

- User-friendly and streamlined operation made bending easy

- Mechanical forced synchronization technique

- Reliable and Accurate Positioning with High-precision Magnetic Scale

- The workbench length ranges from 1200mm to 6000mm

- Top-tier components from leading brands

- Ideal for medium-scale metalworking operations

Hydraulic Press Brake Structure

Compact machine body design, occupying minimal space. Modern machine body design. Our NC hydraulic press brake machine body adopts a three-plate structure with two C-frame frameworks on the sides. The welded box-type bed structure design, heavy side frames, and steel torsion bar ensure maximum strength and rigidity of the machine body.

Our factory has its own precision machine tool processing center, equipped with a large number of modern precision machine tools that not only ensure the quality of the machine body but also achieve cost advantages unmatched by other manufacturers.

- The machine body frame is constructed using integrated welding and top-notch welding craftsmanship, ensuring the stability of the machine body during operation.

- The worktable is made of high-strength and corrosion-resistant carbon tool steel, ensuring minimal wear and long service life.

- Our hydraulic press brake undergoes rust removal with sandblasting and is coated with anti-rust paint.

Shot blasting, top-notch welding craftsmanship, high-strength steel material.

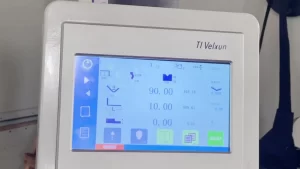

Cybelec 8 controller

Originating from Switzerland, Cybelec’s CybTouch 8 is specifically developed for synchronized NC hydraulic press brake. CybTouch 8 is a mature CNC system that ensures high precision and stability in sheet metal processing while maintaining a user-friendly operating interface. Our control system (TI Velxun) is specifically tailored using Cybelec’s CybTouch 8, incorporating high-performance chips from Texas Instruments (TI). Moreover, the algorithms have been meticulously optimized to meet the unique requirements of our machines.

- The standard configuration is 3 axes, namely X+Y+R axes. Optional X+Y axis.

- It features an intuitive and high-contrast color touch screen and highly integrated functionality.

- Angle, pressure management. Automatic angle correction.

- Programming capability for multiple bending cycles and achieving efficient batch production.

- Our hydraulic press brake provides the alternative of selecting DELEM’s CNC control system.

Easy-to-use programming features for multi-step bending operations.

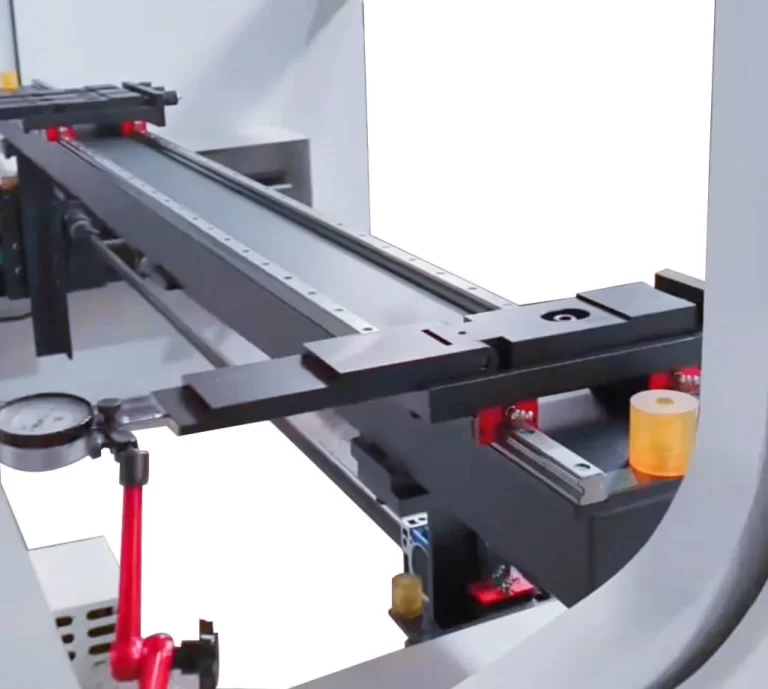

Backgauge

Velxun’s NC hydraulic press brake features a high-speed backgauge sourced from Taiwan Hiwin, incorporating a precision recirculating ball screw and linear guide rail. This advanced design ensures X and R axis positioning error is reduced to ± 0.01 mm. This level of precision allows for the production of complex and intricate parts with tight tolerances, meeting the stringent requirements of various industries. Our hydraulic press brake allows operators to easily program desired dimensions, positions, and sequences, reducing the learning curve and minimizing errors.

- Programmable NC back gauge with variable speed.

- Linear guides and ball screws are highly durable and require low maintenance.

- Suitable for workpieces that require precise bending with multiple steps.

- Standard configuration X+R axes.

- Driven by servo motor.

- Positioning accuracy ± 0.01 mm.

Smooth operation and ultra-low failure rate.

Hydraulic Components

Our NC hydraulic press brake’s hydraulic system components are sourced from top-tier brands worldwide. The hydraulic valves are from Bosch Rexroth in Germany, and the hydraulic pumps are from Sunny in the United States. Our hydraulic system features an integrated structure, ensuring minimal oil leakage risks with the lowest number of pipeline connections.

Velxun’s hydraulic press brake is designed for precision sheet metal processing. Y-axis synchronization with a tolerance of 0.005mm is achieved by implementing optical linear scales on both sides.

Quick response.

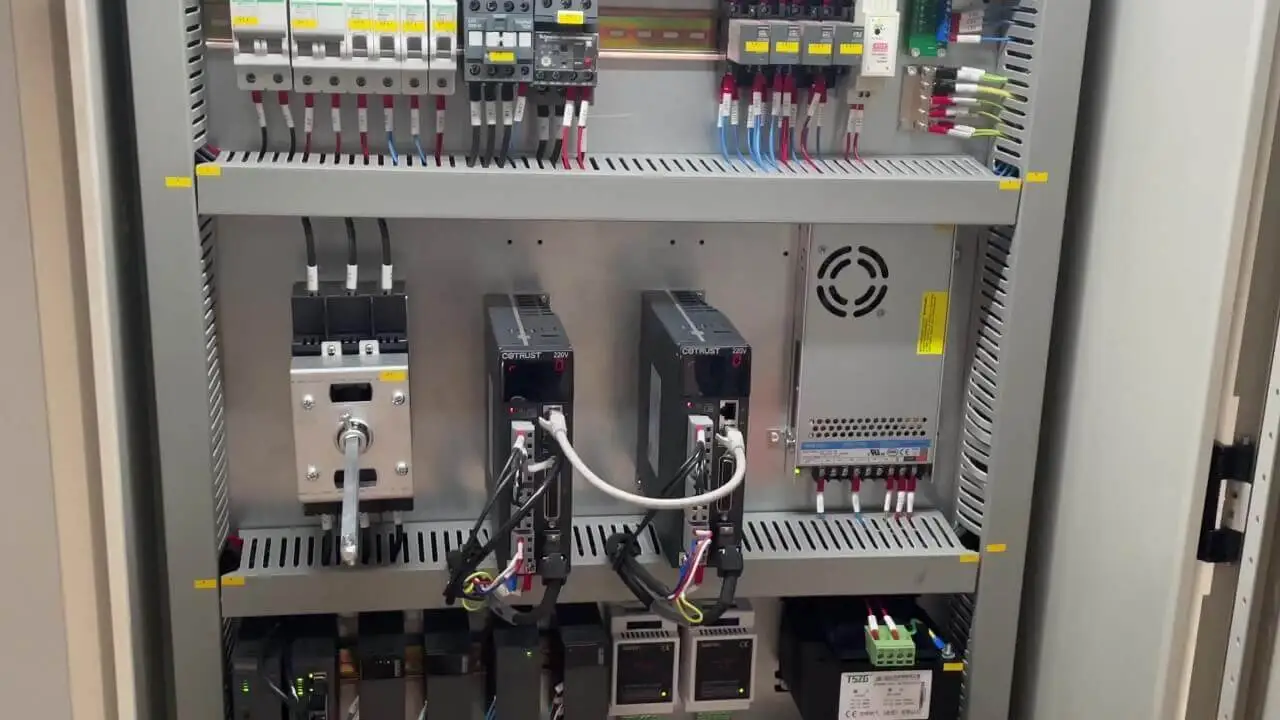

Schneider Electrical Components

Velxun’s hydraulic press brake adopts Schneider electrical components, renowned for their high quality and reliability in the industry. Equipped with a dual-channel safety relay.

Our hydraulic press brake includes features such as short-circuit protection, overload protection, and fault detection systems, ensuring the safe operation of operators and minimizing the risk of accidents.

High quality and reliability.

Easy Clamping System

Our hydraulic press brake’s easy clamping system with a high level of stability enhances the repeatability and consistency of the production process, resulting in high-quality, uniform bends across multiple workpieces.

- Operator-Friendly Design.

- Safety and Durable.

- Simple push-button loading, one-key release fast clamp.

- Secure against tools falling down.

Durability and longevity.

The issues you care about

What category does this press brake belong to?

The full name of this series of machines is "NC torsion-sync hydraulic press brake," but a more concise term for it is "NC hydraulic press brake." "Torsion-sync" refers to the synchronous mechanism of the machine.

What is a Torsion-sync Hydraulic Press Brake?

Torsion-sync Press Brake is categorized of hydraulic press brake based on its working principle and control system, which utilizes a torsion bar system for synchronizing the movement of the ram and the bending beam. Due to its relatively simple structure, it is a more economical choice compared to electro-hydraulic servo press brakes.

What is the positioning of this machine in your product lineup?

We position the Torsion-sync Hydraulic Press Brake as a cost-effective solution without compromising on quality and performance, which is an essential machine for various industries involved in metal fabrication and bending operations. It is our most cost-effective choice in the press brake category and can cater to the majority of sheet metal processing scenarios. It is particularly well-suited for small to medium-scale operations and cost-sensitive start-up enterprises.up enterprises.

How long does it take to learn how to operate this machine?

The CNC system of this machine is designed to be user-friendly, allowing operators to go from basic usage to becoming proficient within typically a week. If the operator has prior experience with press brakes or similar machinery, the learning process may be quicker.

What is the warranty period for the WC67K series hydraulic press brake?

We offer a one-year warranty for the entire machine.

Why are your press brakes relatively inexpensive?

- It is well-known that China is the center of global manufacturing, and our factory is located in Dongguan, the core of China's manufacturing sector, and our factory is located in the heart of China's manufacturing sector in Dongguan. This region has a more complete industrial chain and a comprehensive range of industrial solutions.

- Our factory has been established for over thirty years, forming a close cooperation with upstream and downstream partners in the industrial chain, which enables us to achieve cost advantages that other press brake manufacturers cannot.

- Moreover, we have our own machine tool processing center, where a large number of precision intelligent machine tools help produce machinery from scratch, saving a significant amount of processing costs.

- Our substantial R&D staff is dedicated to improving machine performance while reducing costs, fostering a sustainable development for the company in the long term.

Kristoff Beckett –

This hydraulic press brake has a high production speed. After using it for a month, I quickly placed an order for another one.

Lucas Harrington –

We have found the NC hydraulic press brake to be an excellent investment. Its robust construction and high-quality materials ensure long-term reliability, even under heavy usage.

Peter Dixon –

The hydraulic press brake exhibits superior build quality, ensuring reliable operation in our manufacturing processes. From the selection of materials to the precision machining and assembly, every aspect is carefully executed to ensure accurate and repeatable bends. Its precise control and accurate positioning guarantee uniformity in the finished products, minimizing variations and ensuring the highest standards of quality.

Eric Morgan –

The hydraulic press brake offers comprehensive installation guidance and support. The sales team arranges practical sessions where we can witness the machine’s performance, capabilities, and ease of use firsthand, allowing us to make well-informed decisions.

Benjamin Reynolds –

Velxun’s NC hydraulic press brake’s economic energy consumption leads to cost savings. Its efficient energy utilization reduces electricity bills. Its components are designed for durability and reliability, reducing the need for frequent repairs.

Samuel Foster –

Velxun’s hydraulic press brake sales team is highly responsive and knowledgeable. The sales team provides clear and itemized quotations, highlighting the costs and any optional features or accessories, helping us make budgetary decisions with confidence.

Edward Collins –

The NC hydraulic press brake features angle programming capabilities for complex bends and shapes. It enables accurate alignment and repeatability, making it suitable for intricate and multi-step bending operations, enhancing the machine’s versatility.

Stephen Brooks –

The NC hydraulic press brake boasts an extended lifespan that ensures prolonged productivity. Its high-quality components and robust design ensure a long machine lifespan, providing us with a reliable asset for years to come.

Jeremy Simmons –

Velxun’s hydraulic press brake’s intuitive programming options streamline our workflow. Its fast operation and quick setup capabilities enable us to complete bending tasks swiftly, ultimately increasing our overall productivity.

Nathan Turner –

As a small or medium-sized enterprise, finding cost-effective machinery is crucial, Velxun’s hydraulic press brake meets this requirement, despite its reasonable price, it maintains high-quality standards, making it a budget-friendly option for businesses seeking reliable steet metal bending solutions.

Lawrence Parker –

Velxun’s NC hydraulic press brake is built to endure the demands of continuous operation. It is equipped with advanced safety features, including emergency stop buttons, safety guards, and overload protection mechanisms. Safety is a top priority, and this machine excels in that aspect.

Stephen Brooks –

This machine offers versatility in terms of the range of materials it can handle and the various bending applications it can accommodate. The end results it produces are of high quality, meeting our strict standards.

Eric Phillips –

Velxun’s NC hydraulic press brake consistently delivers precise bends, ensuring that our production process remains efficient and consistent.

Alexander Mitchell –

This machine offers excellent value for the price. It provides advanced features and performance at a competitive price point, making it a cost-effective investment for our business.

Nicholas Ford –

The stability of this hydraulic press brake is truly impressive. It maintains consistent accuracy throughout the bending process. Its competitive price point combined with its outstanding performance and durability make it a top choice for cost-conscious buyers. We can complete more jobs in less time, resulting in higher output.