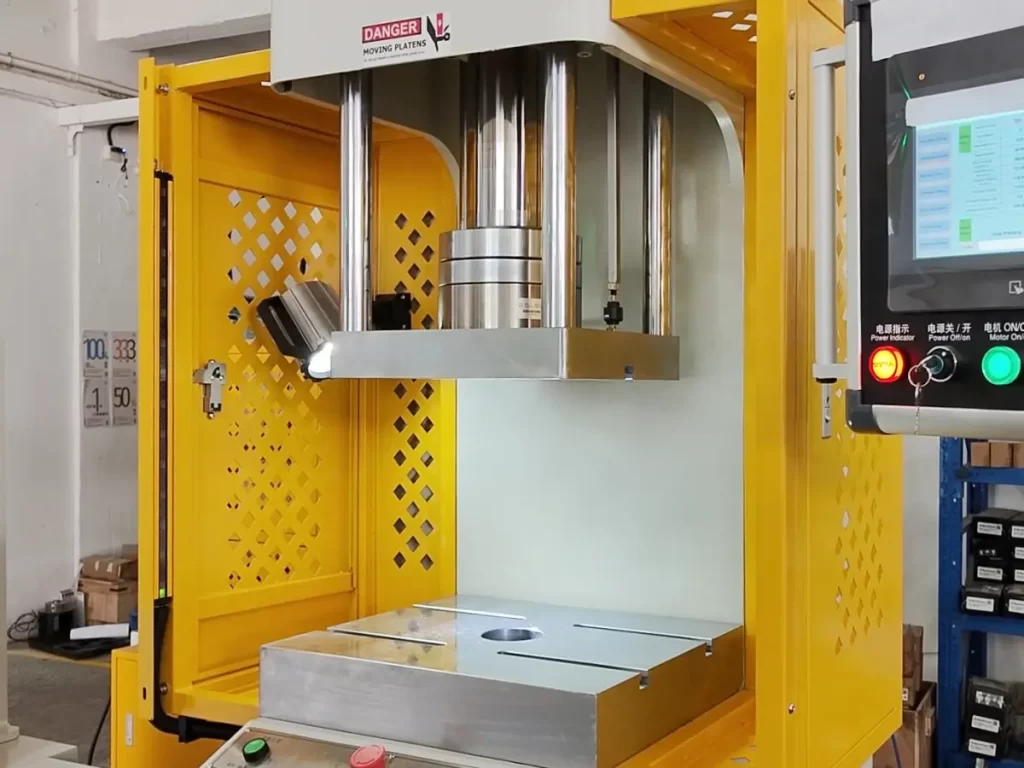

Custom Benchtop Hydraulic Press

All parameters can be customized to suit your business, but the price remains close to standard models.

Youtube Video

Components of the Benchtop Hydraulic Press

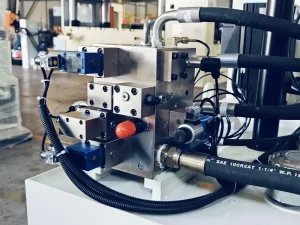

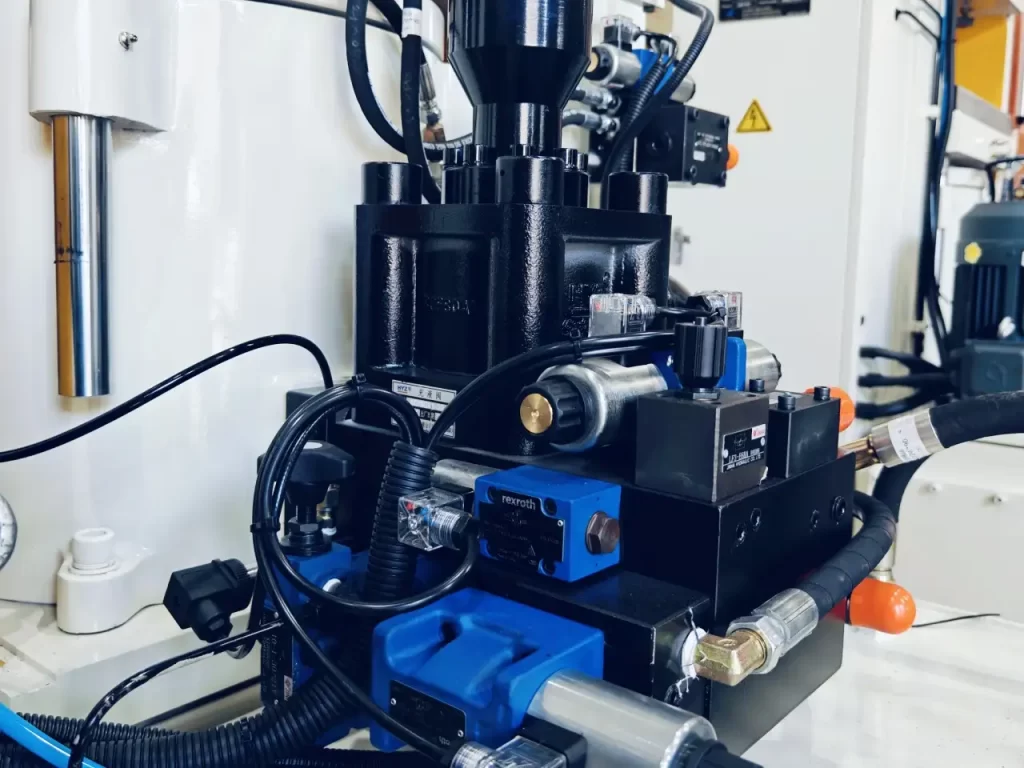

Hydraulic System

360-Degree Rotating Arm

2 of 9WEINVIEW Intelligent Control System

3 of 9Safety Guard and Safety Light Curtains

4 of 9Electrical Cabinet

5 of 9Customizable Workbench

6 of 9Dual-Hand Pneumatic Buttons and Emergency Stop Button

7 of 9Discharge Port (Optional)

8 of 9 Internal ViewServo Motor and Hydraulic Oil Pump

9 of 9

Technology and Application

Assembly Work

The benchtop hydraulic press focuses on high precision and medium-to-small pressure, making it ideal for assembling precision small parts, such as automotive components and electronic products.

Processing Heat-Sensitive Materials

It can be equipped with an optional heated workbench, used for processing heat-sensitive materials such as plastics or composites, especially for new energy materials.

Heated Platen PressPress Fitting

It is often used to press one part into another, such as bearings or gears, and is well suited for combining with automated production lines to improve efficiency.

Stamping and Forming

Frequently used for stamping and forming small metal parts, such as small casings and connectors.

Product Testing

Thanks to the benchtop hydraulic press's precision and flexibility, it is widely used in fields such as material pressure testing or fatigue testing.

Experiments and Education

Due to its high customizability and low cost, the benchtop hydraulic press is often used in various types of experiments and teaching in laboratories, educational institutions, and schools.

FAQs

What is a benchtop hydraulic press?

What are the uses of a benchtop hydraulic press?

How to purchase?

Submit your specific needs through the inquiry portal on our website, and our sales representative will provide you with a quote and guide you through the payment process.

What is the production lead time?

Our benchtop hydraulic presses are custom-made, and depending on the complexity, the production lead time is approximately 3-5 weeks.

How to maintain and care for a benchtop hydraulic press?

- Regularly replace the hydraulic oil, recommended annually.

- Regularly replace seals to prevent hydraulic oil leaks.

- Periodically check whether all moving parts and connections are secured.

- Regularly clean the machine to prevent dust from entering the interior.

- Clean the hydraulic oil tank regularly to ensure the cleanliness of the hydraulic system.

- Regularly inspect the electrical system, check if connections are reliable and if any electronic components are damaged.

- Run the machine regularly; do not leave it idle for long periods to avoid component failure.

Machine Main Body

Our benchtop hydraulic press typically uses a C-frame hydraulic press as the main structure with a benchtop base. The operator can operate the machine while standing without needing to move their body.

- Safety metal guards are optional on both sides.

- Caster wheels are optional at the bottom.

- 360-degree movable control panel.

- Front-mounted two-hand start buttons and emergency stop button.

Intelligent Control Panel

The benchtop hydraulic press uses a control panel from WEINVIEW, Taiwan, which is widely used in small and medium-sized hydraulic presses.

- Simple and clear operation, low learning cost.

- Strong automation integration capabilities.

- High-level protection standards, dustproof and waterproof, suitable for industrial environments.

- Remote monitoring and control, allowing operators or technical support teams to troubleshoot issues remotely.

- Real-time monitoring and feedback, data recording, and analysis.

Customizable Workbench

Our benchtop hydraulic press offers customizable workbenchs, with a variety of optional functions to meet your business needs.

Including but not limited to the following functions:

- Heated workbench (optional)

- Ejector hydraulic cylinder (optional)

- Air-blowing device (optional)

- Lighting system (optional)

- Automatic chip removal function (optional)

- Automatic loading and unloading system (optional)

- Movable workbench (optional)

Intelligent Energy-Saving Hydraulic System

Our benchtop hydraulic presses use top-brand hydraulic valves and pumps, paired with high-performance servo motors, providing stable, reliable performance and a low-noise working environment.

- Equipped with a high-efficiency oil cooling system and hydraulic oil filters.

- Bosch Rexroth modular hydraulic valves and ECKERLE silent hydraulic pumps from Germany.

- Large capacity oil tank, extending work cycles and reducing maintenance requirements.

- Equipped with internationally energy-efficient motors, not only saving energy but also reducing maintenance costs.

- Low-noise and vibration-reduction design significantly reduces noise pollution in the work environment.

Support and Warranty

Our benchtop hydraulic press offers comprehensive pre-sales and after-sales support, with our professional sales team providing full assistance from inquiry to purchase.

- One-year full machine warranty and a three-year frame warranty.

- Online courses and training materials, offering remote guidance and professional training.

- On-site machine maintenance available.

- Comprehensive spare parts supply to ensure quick replacement of critical components, reducing downtime.

Mac –

Nice press

David.T –

Purchased this for my garage workshop and couldn’t be happier. Used it extensively for automotive work

Paul Garcia –

Excellent press for woodworking applications.

Jacob Wright –

Perfect for my blacksmithing and metalworking projects.

Matthew Brown –

Exceptional quality for the price point. I’m a mechanical engineer and use this for prototyping and small production runs.

Robert Williams –

Outstanding performance for my small fabrication shop. The 10-ton capacity handles everything I throw at it.