Manufacturing Process & Technical Parameters

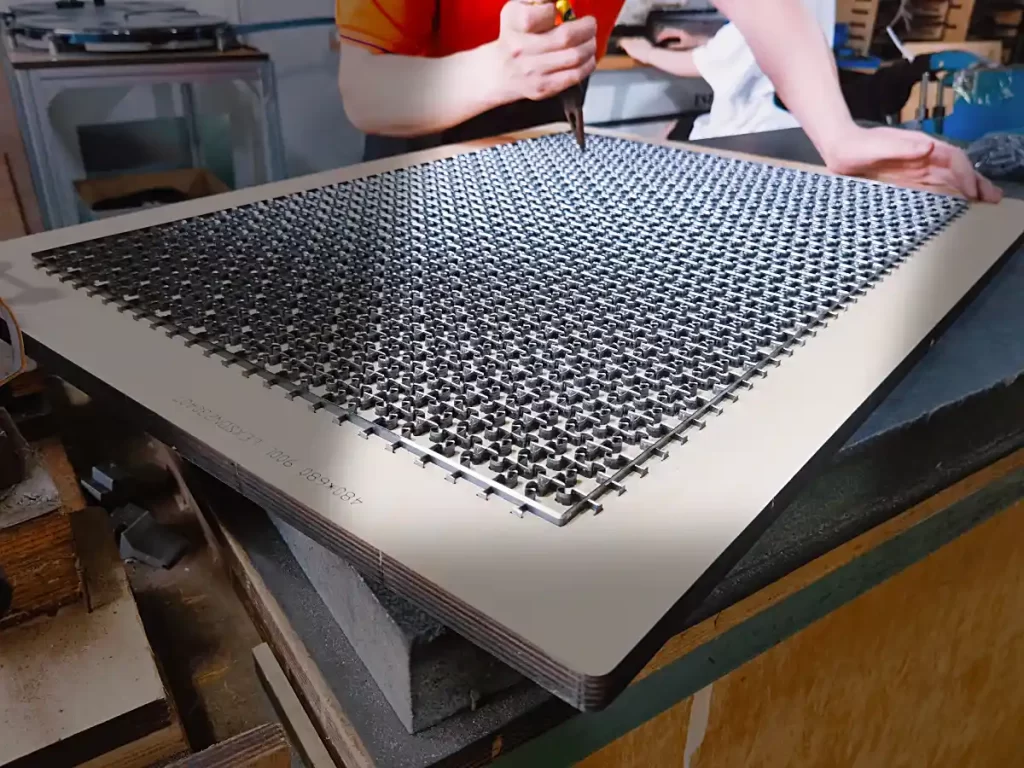

Manufacturing Process

- Customer provides the design file (or we provide design services).

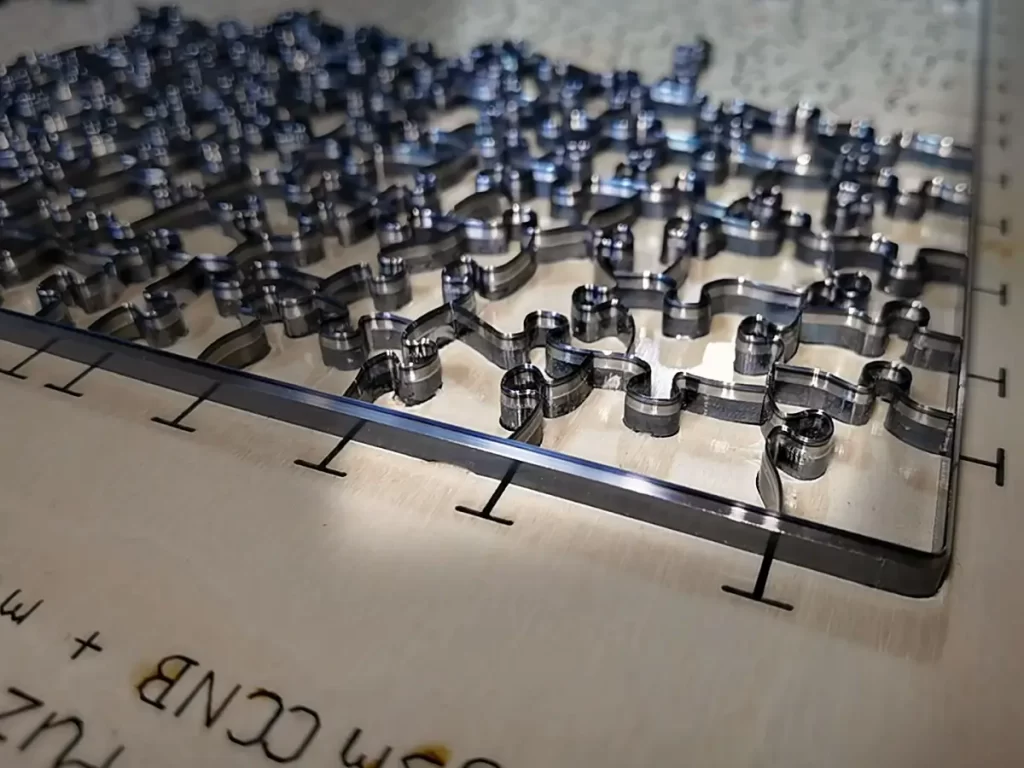

- CAD/CAM layout preparation.

- Laser cutting of the die baseboard.

- CNC bending of steel rule blades.

- Manual blade insertion.

- Insertion of high-elasticity ejection rubber.

- Consistency check and cutting test.

- Final delivery to the customer.

Lead Time

Depending on the complexity of the puzzle cutting die, delivery is within 2–10 working days.

Technical Parameters

Precision: Tolerance controlled within 0.05 mm.

Service life: Between 200,000–500,000 cutting cycles.

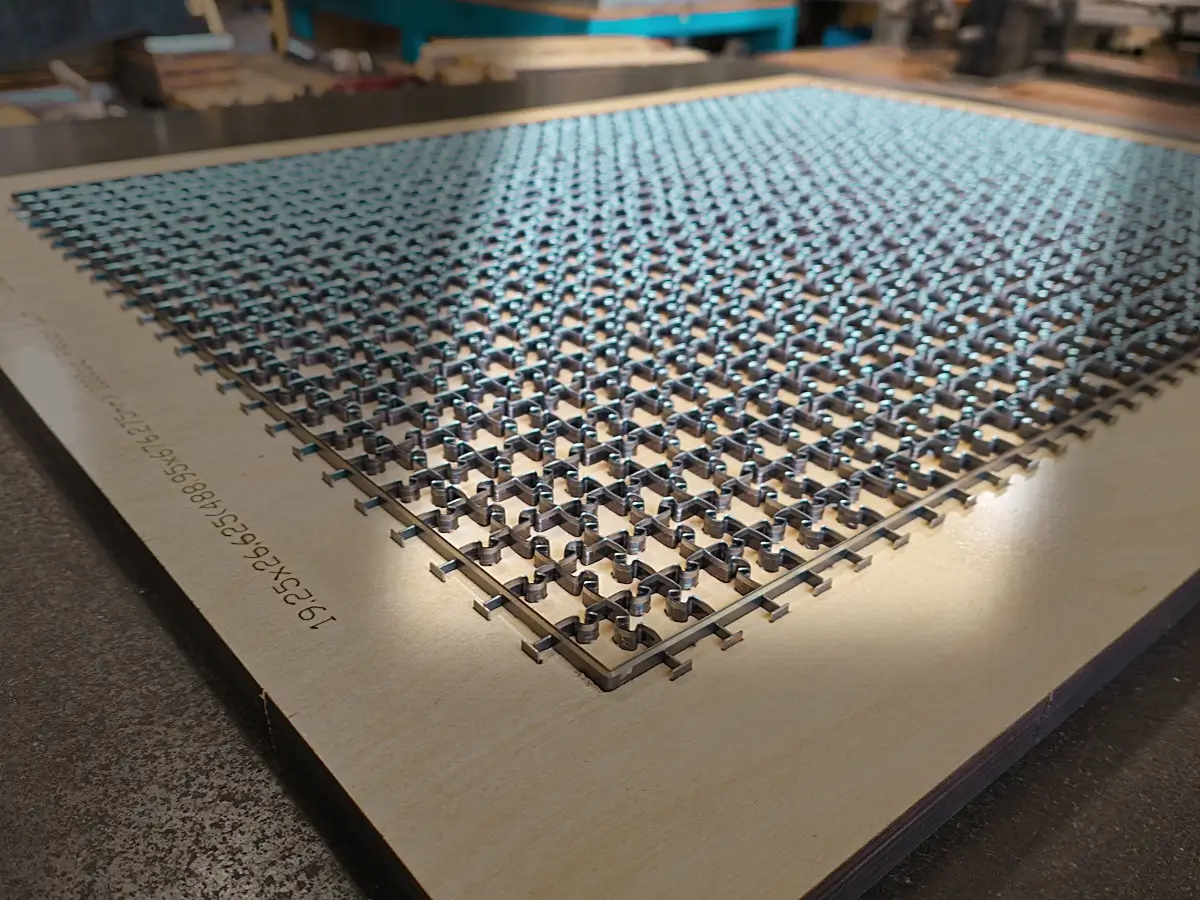

Blade Thickness

2pt (0.71 mm): Suitable for 1.6–2.0 mm board.

3pt (1.05 mm): Suitable for >2.0 mm board.

Baseboard Options

Birch plywood (optional): Cost-effective.

Metal base (optional): Longer lifespan, reusable.

Why Choose LEXSON

High consistency: Strict quality control and a team of technicians with 20+ years of experience.

Premium Components: Only uses top international-grade steel rules, baseboards, and ejection rubbers.

Global clients: Exported to over 30 countries, with an extensive network of partners.

Best Value: Among puzzle cutting dies of equivalent quality, LEXSON consistently offers the best cost-performance ratio in the industry.

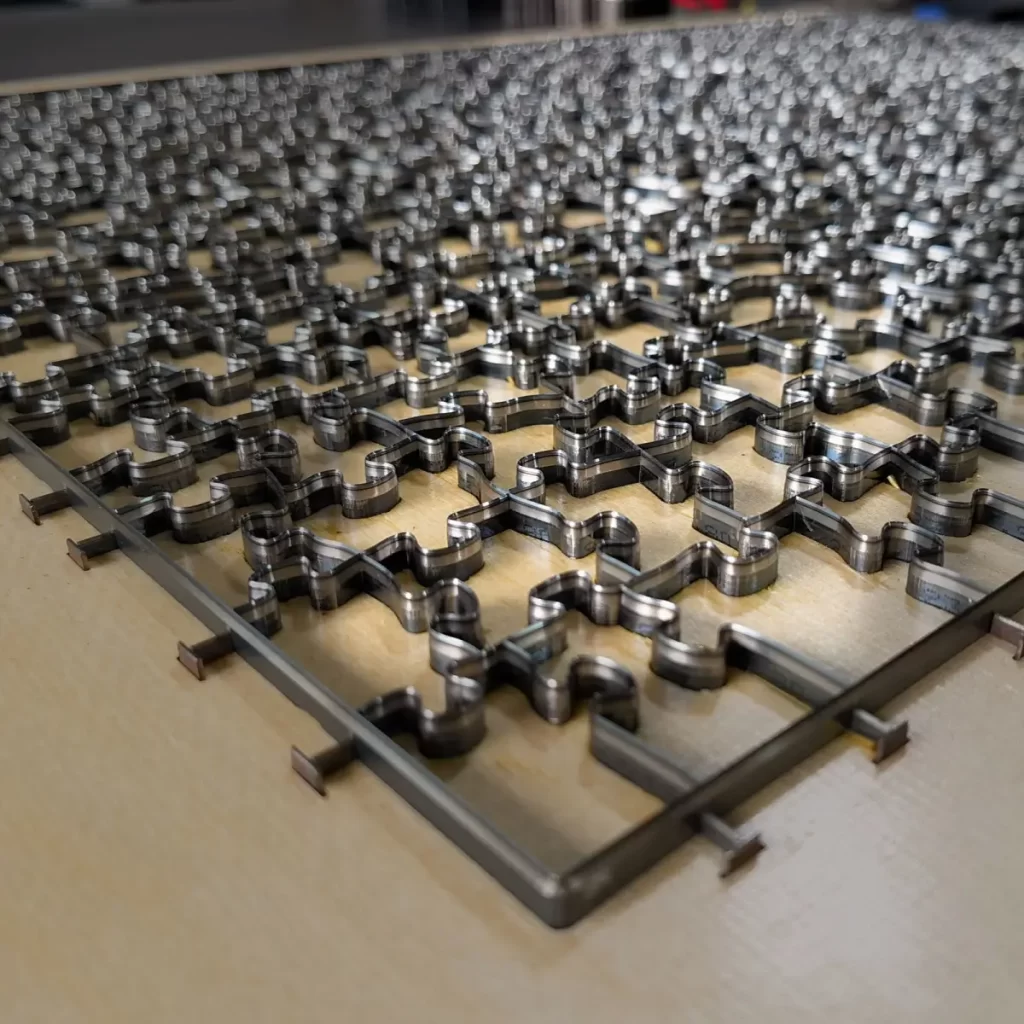

Common Styles of Puzzle Cutting Dies

The common styles of puzzle cutting dies can be generally classified into the following types:

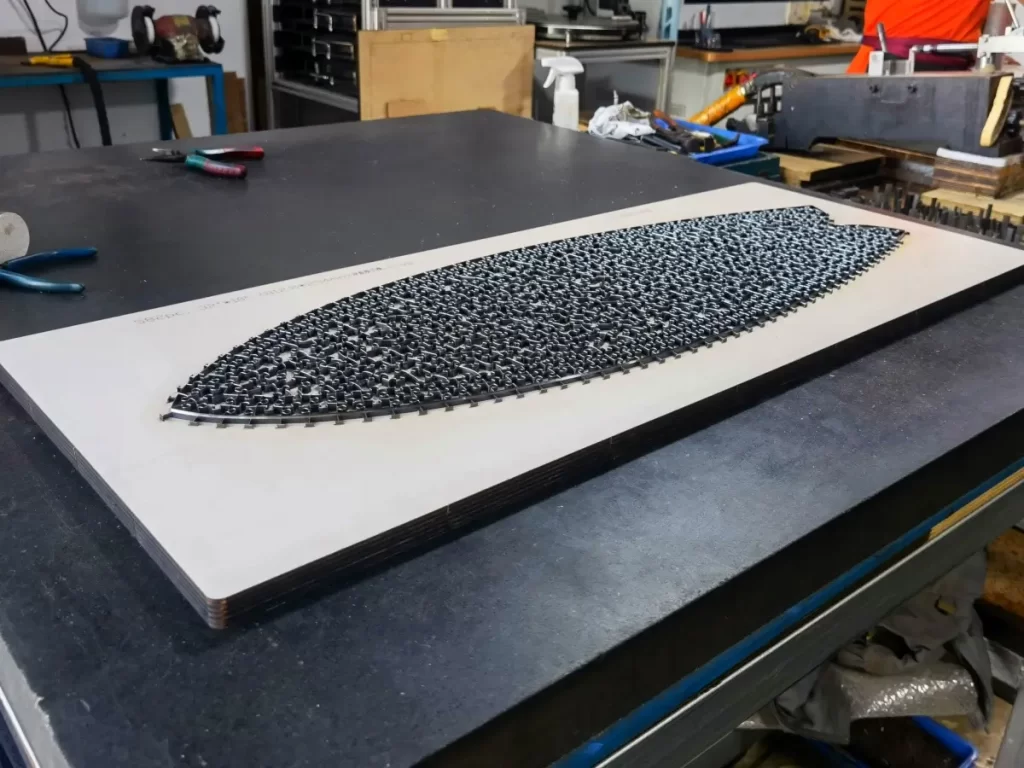

Random Cut: Irregular shapes and sizes, ideal for adult puzzles.

Ribbon Cut: Traditional row-and-column cut, uniform piece shapes; suitable for all ages.

Whimsy Cut: Customized thematic shapes (e.g., animals, logos), suitable for all ages.

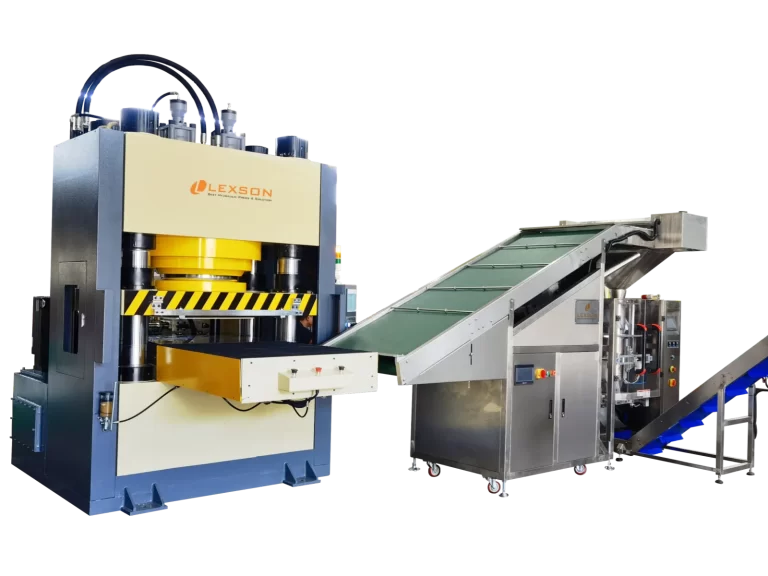

Applicable Boards

Puzzle cutting dies are commonly used on the following types of boards:

- Grayboard: Typically 1.6–2.2 mm thick, generally matched with 2pt (0.71 mm) dies.

- Blue Core Board: Typically 1.6–2.3 mm, cut with 2 pt (0.71 mm) dies.

Conclusion

With over 20 years of expertise, LEXSON provides one-stop solutions for puzzle cutting dies, from design to finished products. Our high-quality dies are trusted by clients in 30+ countries worldwide. For any inquiries, please feel free to contact LEXSON—we are always happy to serve you.