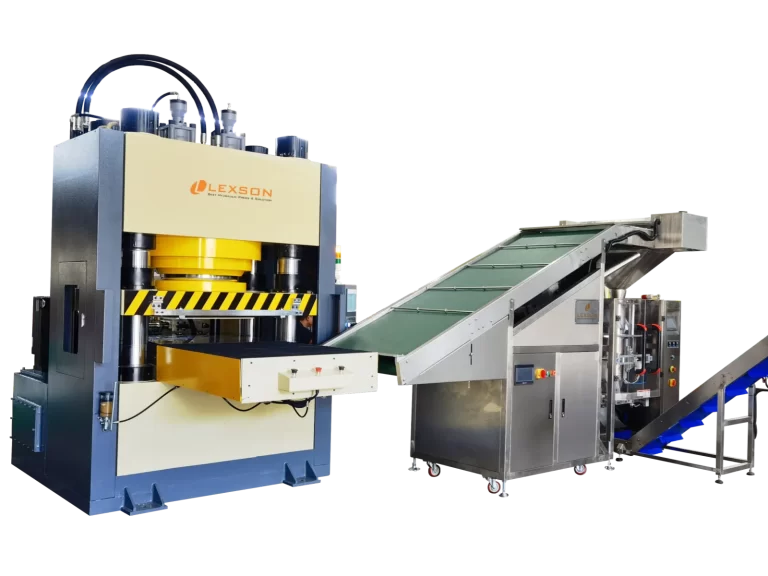

Introduction to Heated Platen Presses

Heated platen presses are specialized industrial machines equipped with one or more heated platens. By setting the temperature and heating time, the press applies pressure to the workpiece. The main heating methods include electric heating, oil heating, and steam heating. Heated platen presses are widely used in thermoforming, bonding, laminating, and related manufacturing processes.

Heating Methods and Characteristics

Electric Heating

Principle

Electric heating involves embedding resistance heating elements inside the platen. When current flows through the resistance wires, Joule heat is generated, converting electrical energy into thermal energy, which is then transferred to the platen surface. This is the most widely adopted heating method in heated platen presses.

Features

- Fast heating rate

- Precise temperature control

- Moderate temperature uniformity, heavily dependent on layout for large platens

- Zoned temperature control required for large platens (edge heat dissipation necessitates independent control of multiple heating elements)

- Low system complexity and maintenance cost

- High operational safety

- Relatively low purchase cost

Applications (examples)

- Wood processing

- Rubber and plastic molding

- Composite material curing

- Research, laboratory testing, and material experiments

- PCB lamination for electronic products

- New energy components (photovoltaics, batteries)

- Educational and experimental presses

Temperature Range

Electric heating generally supports temperatures ≤ 450℃.

Summary

Electric heating is the most common method, ideal for small to medium platen sizes, applications requiring precise temperature control, and users seeking a cost-effective solution.

Oil Heating

Principle

In oil heating, thermal oil circulates through internal pumps and channels inside the platen, transferring heat via thermal conduction. This method is commonly used in medium- and large-scale heated platen presses and provides excellent temperature uniformity.

Features

- Excellent temperature uniformity

- Slower heating rate, requiring preheating

- Capable of continuous long-term operation

- Designed for medium- and large-scale production

- Relatively high purchase cost

- Requires periodic replacement of thermal oil

- Higher maintenance cost

Applications (examples)

- Medium- and large-scale construction materials and wood processing

- Fireproof panels and decorative veneer lamination

- High-performance carbon fiber manufacturing

- Food packaging film lamination

- BMC/SMC molded parts

- Rubber vulcanization

- Medium- and large-scale PCB lamination

- Medical composite material sterilization and sealing

Temperature Range

Oil heating generally supports temperatures ≤ 350℃.

Summary

Oil heating is ideal for large platens and applications that demand extremely high temperature uniformity, such as aerospace composites and premium laminates.

Steam Heating

Principle

In steam heating, high-temperature, high-pressure steam is generated by a boiler and transferred through internal piping within the platen, delivering heat to the workpiece. Although the maximum achievable temperature is lower, this is a cost-effective and widely used traditional heating method.

Features

- Low energy consumption

- Lower maximum temperature

- Very fast heating speed

- High thermal efficiency

- Moderate temperature control accuracy (±5℃ or higher)

- Lower equipment cost, but requires a central steam supply system

Applications (examples)

- Wood processing (e.g., plywood, particleboard)

- Low-temperature paper lamination

- Textile composite bonding

- Low-temperature rubber vulcanization (e.g., conveyor belts, shoe soles)

Temperature Range

Steam heating generally supports temperatures ≤ 180℃.

Summary

Steam heating is an economical heating method suited for applications with low temperature and uniformity requirements, commonly used for large-scale processing of wood, rubber, and other mid-to-low-temperature materials.

Conclusion

Electric heating, oil heating, and steam heating each have their advantages and disadvantages, making them suitable for different production scales and process requirements.

Electric heating offers rapid heating and precise control, ideal for small-to-medium presses and R&D environments. Oil heating provides excellent temperature uniformity, making it suitable for large-scale production and high-end composite materials. Steam heating provides cost-efficiency and is commonly used in large-batch, mid-to-low-temperature production, such as wood and rubber processing.

We customize the most suitable heated platen press based on customer materials, temperature ranges, and production scales. Contact LEXSON engineers today to obtain a personalized solution designed to help you overcome capacity and quality bottlenecks.

In future updates, we will explain the differences between various cooling systems for heated platen presses. Stay tuned!