What is a Puzzle Cutting Machine (Puzzle Die-Cutting)?

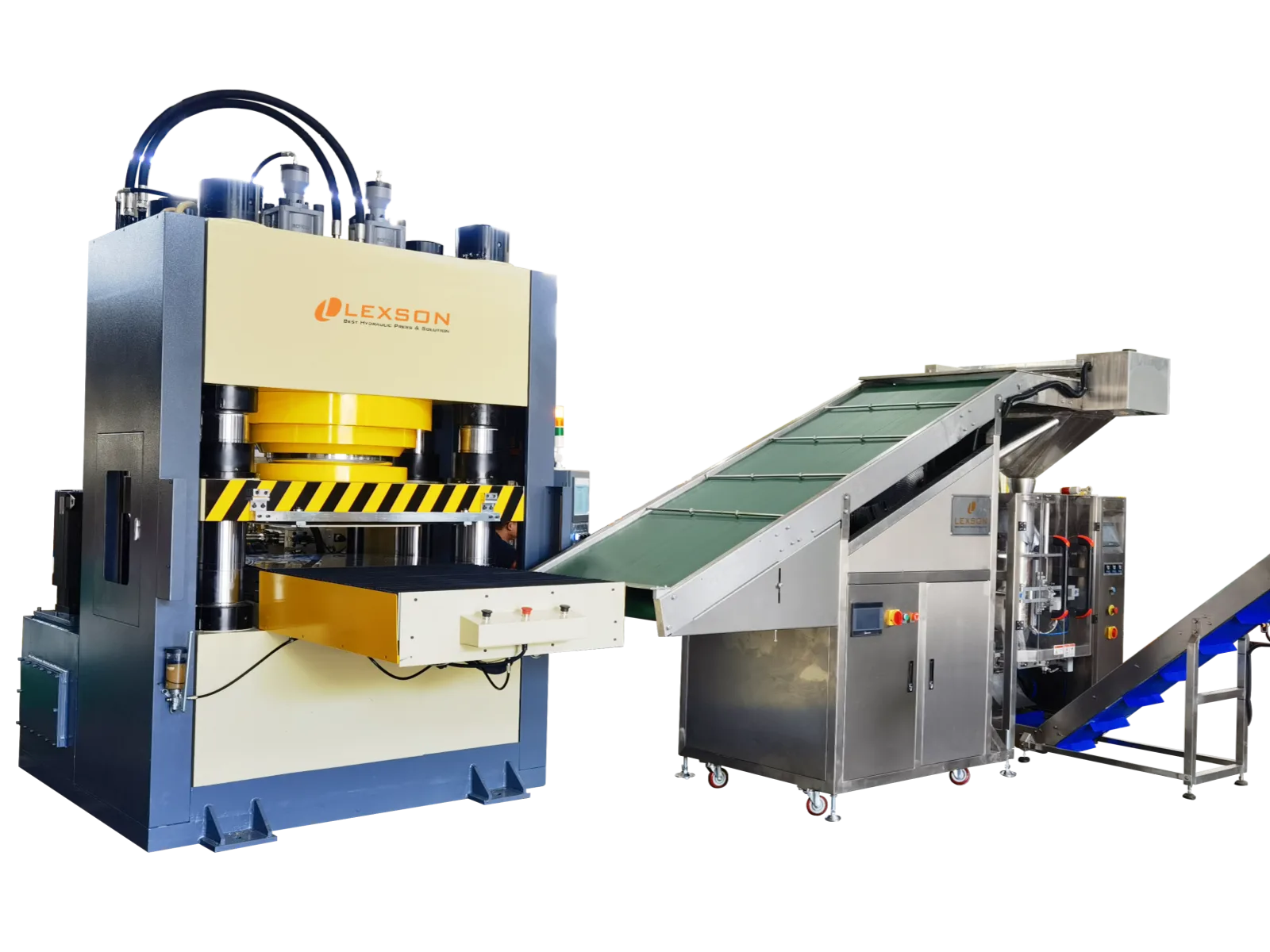

The current mainstream industrial production method for puzzle cutting machine is die-cutting, which is a precision equipment specifically designed for making puzzles. LEXSON puzzle cutting machine uses high-pressure stamping technology to cut entire cardboard according to the shape of puzzle die, forming interlocking puzzle pieces that are widely used in various industrial puzzle production scenarios. Die-cutting technology can ensure batch, stable, and uniform cutting of hundreds or even thousands of puzzle pieces, ensuring tight interlocking between each piece and neat edges, bringing users a better assembly experience.

Puzzle Cutting Machine Working Types

- Die-cutting: Uses hydraulic press and steel puzzle die, durable, high output, fast production speed, suitable for batch production.

- CNC/laser cutting, semi-manual production: Suitable for small batch customization needs, not the main focus of this article.

Puzzle Cutting Machine Applicability

LEXSON Puzzle Cutting Machine Applicable Enterprises

- Small, medium, and large puzzle manufacturers with business expansion needs.

- Puzzle enterprises hoping to save labor costs, increase puzzle output, and improve puzzle production consistency.

- Cross-industry entrepreneurs and startup companies, LEXSON puzzle cutting machine has low learning costs.

- Existing puzzle equipment that is too old, not intelligent enough, or damaged.

Applicable Materials or Substrates

Puzzle Materials

- Standard cardboard puzzle: The most common cardboard puzzle on the market.

- Wooden puzzle: Combined with high-pressure die, cutting thin wooden board puzzle, durable and long-lasting.

- Foam puzzle: Floor covering for children’s play areas, gyms and other places, providing anti-slip, sound insulation, and warmth.

- Plastic: Difficult to mass produce, not the main focus of this article.

Puzzle Carriers

- Personalized customization: Personal DIY pattern puzzle.

- Puzzle frame industry: Used for framing after die-cutting.

- Gift customization industry: Wedding puzzle, commemorative puzzle, corporate custom gift box puzzle.

- Store decoration: Used for wall decoration, puzzle wall is both beautiful and enriches store design sense.

- Cultural and creative merchandise: Enterprise, brand, and artist licensed puzzle.

- Artificial intelligence creation: Using artificial intelligence-created images to produce puzzle.

- Children’s puzzle: Cartoon puzzle, alphabet puzzle, parent-child educational puzzle and other products, within 4-100 pieces.

- Adult puzzle: 100-3000 pieces of complex puzzle targeting the adult market.

Applicable Cutting Quantity (500-2000 pieces)

- Below 300 pieces mostly uses manual or benchtop cutting equipment.

- 500-1000 pieces suitable for LEXSON puzzle cutting machine (LEXSON-A01).

- For 1000-2000 pieces and above, it is recommended to consider using ultra-high tonnage LEXSON puzzle cutting machine (LEXSON-A01-PRO).

- For 3000 pieces and above, it is recommended to use LEXSON puzzle cutting machine (LEXSON-A01-PRO) for multiple cutting sessions.

Why are 500 pieces a watershed?

Puzzle requires high pressure above 600 tons for 500-1000 pieces and above due to multiple cardboard layers (usually 3 layers of blue core paper or wooden board) and complex interlocking structure, must rely on hydraulic press’s high tonnage pressure to ensure one-time cutting through.

Delivery Methods and Machine Specifications

| Brand | Product Name | Certification | Pieces per Cut |

|---|---|---|---|

| LEXSON | LEXSON puzzle cutting machine (LEXSON A01, LEXSON A01 Pro) | UL/CE/ISO | 500-1000 piece puzzle (recommended), 2000 piece puzzle (ultra-high tonnage) |

| Power Support | Warranty Period | Customizability | Technical Support |

| 220V-480V, customizable | 12 months | All machine configurations and parameters can be customized | Debugging and training, remote technical support, long-term supply of wearing parts, operation documentation |

| Production Cycle | Payment Method | Packaging | Delivery Method |

| About 40-60 working days | T/T | Sea freight, wooden box packaging | FOB, EXW, CFR, CIF, DDU |

How to Select a Puzzle Cutting Machine?

Taking LEXSON puzzle cutting machine as an example, customers usually need to pay attention to the following key factors:

Cutting Pressure

Determine hydraulic press pressure based on the number of puzzle pieces cut at one time and cardboard size.

Generally, 500-piece puzzle requires 500-ton hydraulic press.

1000-piece puzzle requires 600-700 tons of pressure, 600-ton hydraulic press can meet most puzzle cutting needs.

Thicker or higher density cardboard is recommended 700 tons or above.

1000-2000 pieces recommend 800-1300 tons of pressure.

LEXSON puzzle cutting machine is equipped with intelligent overload protection system.

Compatible Die Size

According to your commonly used puzzle specifications, confirm whether the machine worktable size can completely cover the die area.

Our machine’s worktable area can be customized according to your needs. Generally, the worktable area is more than 3 times the puzzle size.

Operation Convenience

Machine ease of learning and operation is very critical. LEXSON puzzle cutting machine is suitable for operators of different experience levels and age groups.

Structure and Durability

Preferably choose models with thickened steel plate welded frame and industrial-grade hydraulic system, which can ensure long-term use without failure, wear resistance, and deformation resistance. LEXSON puzzle cutting machine continuous cutting 500,000 times, table deformation ≤0.05mm (national standard ≤0.15mm).

Brand and After-sales

Choose a guaranteed manufacturer, LEXSON puzzle cutting machine can obtain technical support and customization service, while ensuring parts supply and after-sales maintenance guarantee.

Safety Compliance (UL/CE/ISO)

Two-hand trigger button (spacing ≥300mm).

CT4 level safety light curtain (response time ≤20ms).

Emergency pressure relief valve (response time <0.5 seconds).

Production Speed

10 seconds to complete one puzzle cutting, 20 seconds to complete bagging, maximum output 400+ per hour.

Control System

Fully automatic/CNC PLC control: Configured with touch screen, adjustable speed, pressure programming, high efficiency and easy monitoring.

Power Consumption

Using servo motor and drive significantly reduces power consumption.

Servo regenerative drive: Energy recovery power supply saves 40% electricity

On-demand oil supply system: Eliminate no-load loss

Workflow: From Cutting to Bagging

- Preprocessing: Place the printed, glued and laminated static puzzle board on the worktable.

- Positioning and tightening: Start the puzzle cutting machine to align with the die cutting area.

- Pressing and cutting: 4-post hydraulic press applies huge uniform pressure to make the puzzle die cut deeply through the puzzle board.

- Reset and board removal: Machine resets, cut puzzle is pushed out by sliding worktable.

- Puzzle scattering: Transfer the cut puzzle to the conveyor belt, to the puzzle scattering equipment.

- Bagging: Automatically bag the scattered puzzle.

- Subsequent processes: Outer packaging, plastic sealing integrated production line for better results.

How to Maintain the Machine?

Clean

After cutting, it is recommended to clean paper scraps and adhesive fragments around the puzzle die and worktable daily to avoid blade jamming and misalignment.

Inspection and Lubrication

Lubricate bearings and hydraulic press pressure columns every 600 hours or half a year.

Regularly oil moving parts, gears, and slide rails to avoid blockage.

Regularly investigate and detect oil leakage risks.

Hydraulic oil needs to be changed every half year.

Long-term monitoring of hydraulic oil temperature (recommended below 60°C).

Alignment Calibratio

Regularly run trial cutting calibration, fine-tune pressure, die height, and die deviation to ensure cutting consistency.

Die Storage

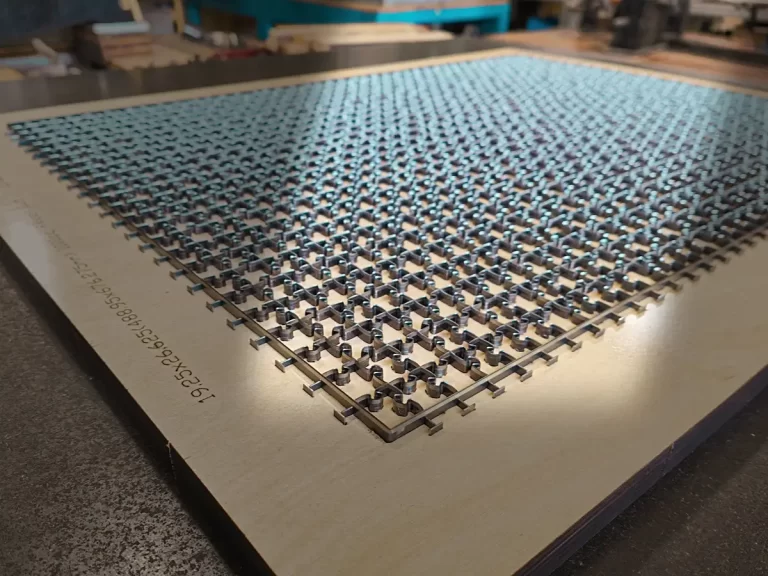

Apply rust-proof oil after cleaning. Store in hanging bags or boxes, hang vertically to prevent deformation, avoid dropping.

Avoid moisture, avoid direct sunlight, avoid hard object scratches, birch base can be waxed regularly.

Regularly check the position of puzzle die blade, check for skewing, breaking and timely adjust or replace blade.

Average life of puzzle die: ordinary puzzle die 20,000-50,000 times, our professional puzzle die can reach 100,000 times or more under proper maintenance.

Maintenance Cycle

Pressure system is recommended to be inspected and calibrated by manufacturer or third party.

Disassemble and inspect key components once a year, replace damaged or cracked parts timely.

FAQ

Are puzzle dies replaceable? Are they universal?

Yes. Just ensure the die size is within the machine worktable range. Support customization of different puzzle specification dies.

Does LEXSON puzzle cutting machine come with die for sale?

Puzzle die is not included by default. If you need die, please contact our customer service to place an order.

How to solve puzzle cutting burrs?

The main four causes are:

Die blunting (requires calibration or replacement).

Insufficient pressure (test by increasing tonnage by 5% each time).

Abnormal cardboard moisture content (control environmental humidity 50%±5%).

Cardboard material does not meet standards and is not suitable for cutting.

How long is the equipment warranty? Is after-sales support provided?

Complete machine warranty for one year, machine frame warranty for three years, lifetime technical support provided.

We provide comprehensive after-sales service including online Q&A, video remote installation assistance, original parts replacement, etc.

Installation, maintenance and repair provided within China (overseas requires payment of round-trip costs).

Does puzzle cutting require manual sorting afterwards?

Can be paired with LEXSON’s puzzle bagging machine for automated puzzle scattering and automatic bagging, greatly saving labor costs.

How many sets of puzzles can be cut at once?

According to material thickness and die area, generally one complete puzzle set can be cut at once (recommended). Some smaller puzzle dies can be arranged side by side for multiple sets, achieving simultaneous cutting of multiple pieces within safety range.

Does operating puzzle cutting machine require professional training?

No professional background required. We provide English/Chinese operation manual and video teaching, equipment is equipped with simple buttons and control system, we can also provide remote guidance if needed, beginners can quickly get started.

Can voltage and plug be customized? Which countries are applicable?

Support 220V/380V/415V/480V and other voltages, European/American/British and other plugs, accept customization. Can adapt to industrial and workshop electrical standards in most countries worldwide.

How many people are needed to operate LEXSON puzzle cutting machine?

Our puzzle cutting machine only requires one person for feeding, from cutting to bagging operations are all automated, saving labor costs, suitable for both small and medium-sized factories or startup teams, and large puzzle manufacturers.

Can laminated puzzle board be cut?

Of course, LEXSON puzzle cutting machine supports precise die-cutting of laminated cardboard, glued surface and other materials, with smooth cuts and no burrs.

The Future is Here: Rise of Intelligent Production Lines

LEXSON puzzle cutting machine customer feedback confirms the trend: “Our intelligent puzzle production line reduced labor costs by 70%, defect rate dropped from 3% to 0.1%.”

In this era where creativity is king, owning a high-performance puzzle cutting machine means having a powerful tool to monetize creativity or AI images. LEXSON provides one-stop solutions for every manufacturer who cares about production efficiency and return on investment.

We hope this article can provide valuable reference for your equipment selection. For more information or equipment details, please consult us for more professional and personalized solutions.