Custom Coining Press Manufacturer

All parameters of the coining press are customizable.

Youtube Video

View components

Pneumatic device

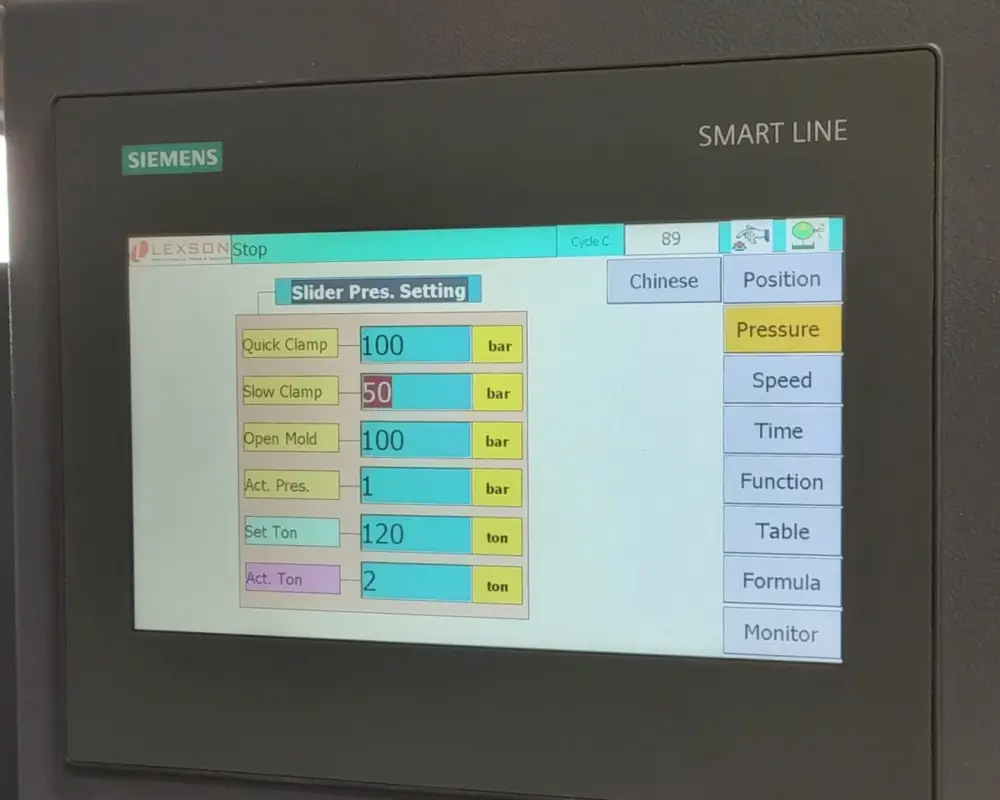

1 of 7Siemens control panel

2 of 7Automatic safety guard

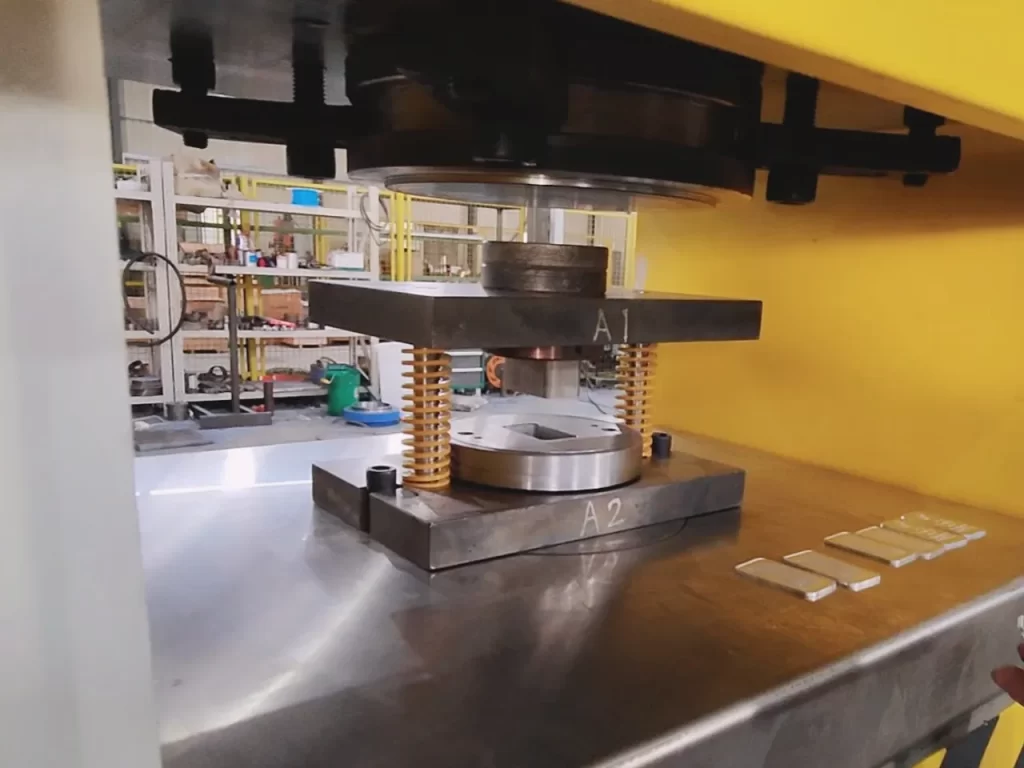

3 of 7Customizable molds

4 of 7Two-hand start switch and emergency stop button

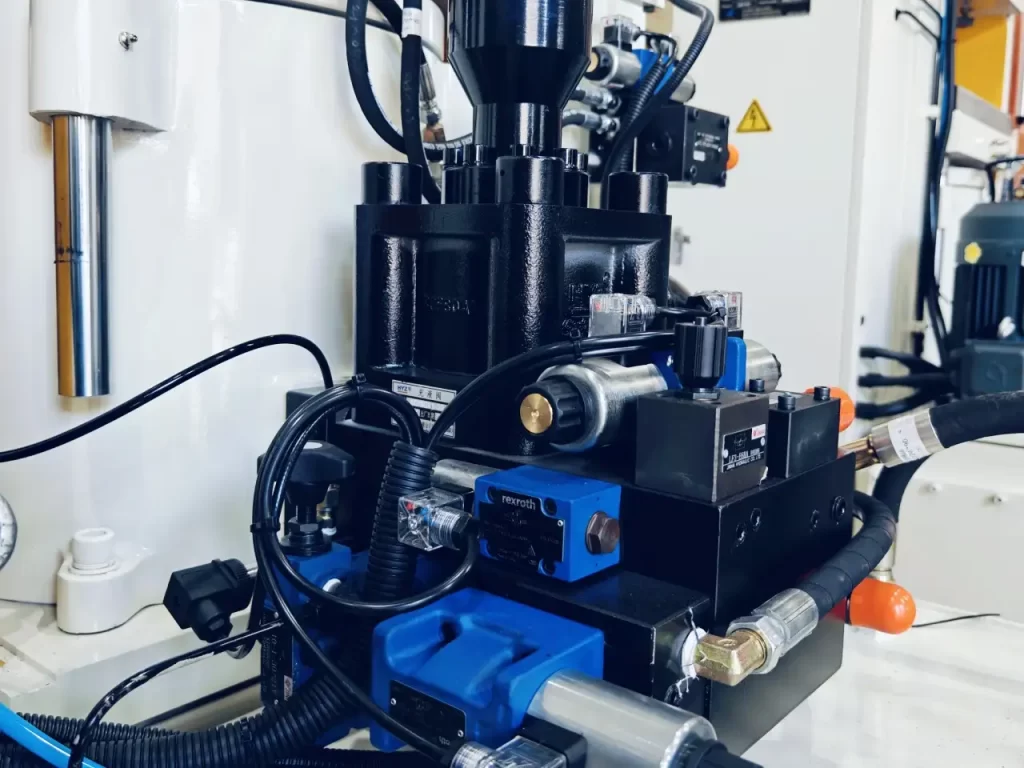

5 of 7 Back ViewHydraulic unit and power system

Hydraulic oil cooler

7 of 7FAQs

What is a coining press?

A coining press is a high-precision hydraulic device typically used for manufacturing coins, medals, commemorative tokens, and other high-precision metal products.

Is your machine custom-made or standard?

Our coining press is custom-made. We can adjust the machine’s size, hydraulic tonnage, automation systems, production speed, and other features according to your specific requirements.

What metals and products are suitable for your coining press?

It is suitable for processing metals like gold, silver, platinum, copper, and alloys. It is widely used in the production of commemorative badges, jewelry, watch cases, lighting fixtures, cutlery, buttons, eyewear accessories, and more.

What are the features of your machine?

Compared to standard motor-driven presses, our coining press saves 50% on energy, offers higher precision, and ensures that the pressed products are scratch-free with excellent consistency. This improves product quality while reducing costs.

Can your machine be integrated into an automated system?

Yes, our coining press can integrate with advanced automation systems, significantly reducing labor costs while maintaining very low maintenance rates under high-intensity usage conditions.

Features of the Coining Press

- Pressure customization: 10-1000 tons

- High-Speed production

- Robust frame

- Minimal maintenance

- Automated production

- 50% energy savings

- Siemens touchscreen

- Servo motor

- Energy-saving and environmentally friendly

- High cost-effectiveness

Machine Structure

The coining press adopts an integrated embedded frame, which ensures excellent stability and uniform force distribution, making it highly suitable for coin pressing. It guarantees a high yield rate, significantly reducing costs.

- The integrated embedded frame is used by default, providing excellent stability and effectively reducing vibration and displacement during the pressing process.

- This frame is compact, requiring minimal floor space.

- Heavy-duty steel frame with an extremely long lifespan, suitable for high-intensity and long-duration work environments.

- The frame undergoes special surface treatment, making it corrosion and rust-resistant.

- Optional four-column hydraulic press, facilitating integration with automation systems, offering greater flexibility.

Pressing Die Area

- Customizable dies can be tailored to any shape and design according to your requirements.

- Ensures precision requirements of the molds, guaranteeing a very high yield rate.

- Full-process infrared protection ensures that the hydraulic press does not impact the dies during the stamping process.

- Optional cooling system, blowing device, ejector cylinder, and more.

Automatic Feeding System and Collecting Device (Optional)

Our coining press can be equipped with an automatic feeding system and collecting device, enhancing efficiency and reducing labor costs.

- Fully automatic feeding and collecting system for an automated production process.

- Powerful yet simple operation with a low learning curve.

- Precious metals are very expensive; automated operations ensure maximum precision in production, reducing the cost of manual operations.

- The system integrates smart technology, enabling real-time monitoring and data collection.

- Improves efficiency and reduces the risk of workplace injuries.

Control Panel

Our coining press is equipped with top-tier control components, with closed-loop control enabling real-time adjustments to ensure a high product yield rate.

- Equipped with German Siemens control panel and PLC, providing excellent control performance.

- Fully automatic, semi-automatic, and manual modes are available.

- Seamless integration with modern Industry 4.0 technologies, enabling data collection and fully automated control through PLC and HMI.

- The closed-loop control system uses sensors to monitor the hydraulic press’s output (position, pressure, speed, etc.) in real-time.

Hydraulic Unit

The coining press offers the most mature and reliable hydraulic unit system.

- Equipped with Bosch Rexroth modular hydraulic valves and ECKERLE silent oil pumps, ensuring excellent hydraulic oil flow control performance.

- The control system automatically adjusts the input parameters of the hydraulic press (such as hydraulic oil flow or pressure) to correct errors, ensuring consistency of the pressed products.

- Leakage prevention design. Includes an oil leakage alarm.

- Hydraulic oil water cooling system and high-efficiency oil filters ensure system stability in high-temperature working environments, extending the lifespan of hydraulic components.

Automatic Safety Guard (Optional)

The coining press is equipped with an automatic safety guard that ensures safety while allowing easy observation of the processing status.

- Multiple safety sensors ensure that operators do not accidentally enter dangerous areas during the pressing process.

- The machine will automatically stop if the safety guard is not fully closed due to entry into a hazardous area, preventing any potential safety hazards.

- Effectively prevents external dust and oil from entering the working area, maintaining the cleanliness and proper operation of the equipment.

Benjamin Harris –

The automatic feeding system is a game changer, making our workflow much smoother.

William Smit –

Customer support has been helpful and responsive.

Robert Davis –

Initially, there were some setup challenges, but once operational, the press performed beyond expectations.

James Stewart –

The press has excellent precision and has boosted our production significantly.

William Bradley –

After comparing several models, we chose this press for its superior build and features.

Henry Briggs –

Excellent consistency in coin stamping. Minimal maintenance needed, which is great for continuous operation.

Charles Brown –

The precision and speed of this press are exactly what we needed to meet our production deadlines.

Ray –

This coining press handles high volumes like a champ.