Industrial Puzzle Making Machine

Our puzzle making machine is equipped with the highest-grade components in the industry while maintaining a competitive price. Enjoy a great value offer when purchasing the full set of equipment. Don’t miss the opportunity to revolutionize your puzzle making process, reduce production costs, and maximize your profits.

Precision Cutting Technology

Wide Processing Range

Smart Series

Long Lifespan

With Exchange or Shuttle Table

Affordable Prices

Complete Solution

Versatility

Top-tier Components

Oil-Resistant Design

Video

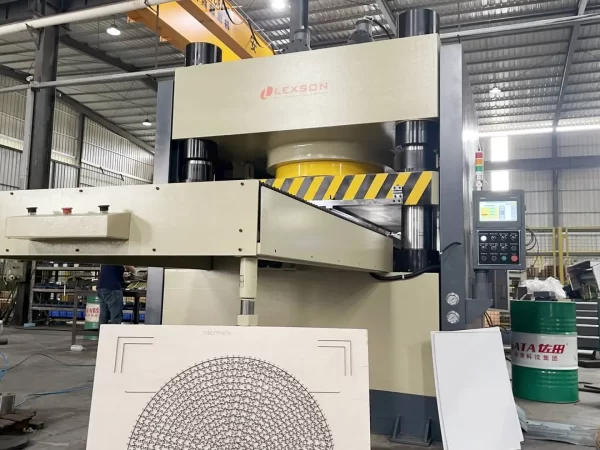

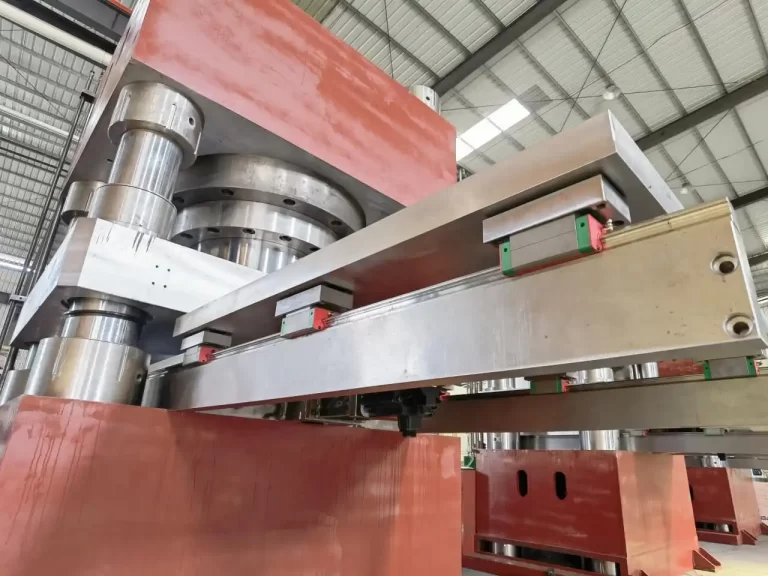

Lexson Series Puzzle Cutting Machine Front View

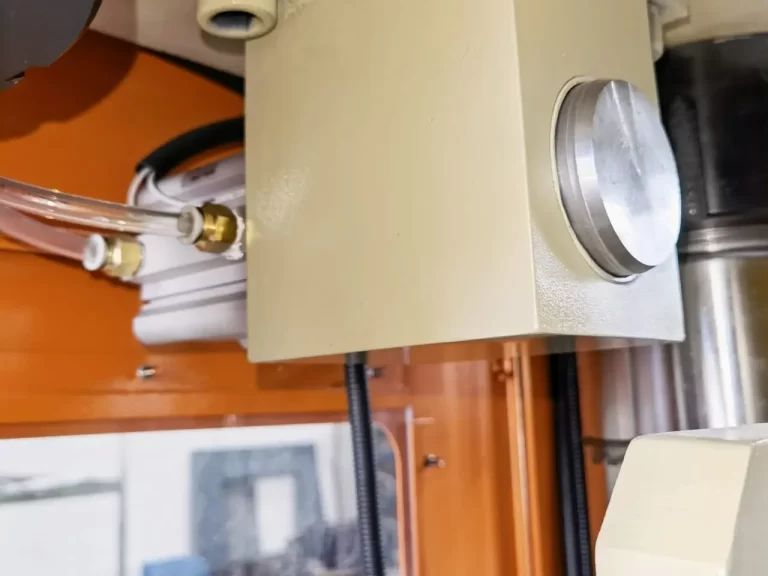

Chrome-plated Posts:

We utilize highly durable bronze bushings, and all hydraulic columns are hard chrome-plated, ensuring smooth operation with low vibration and minimal noise.

1 of 9

Shuttle Table:

We have adopted HIWIN linear guides and DELTA servo motors, ensuring a safer and faster puzzle cutting experience.

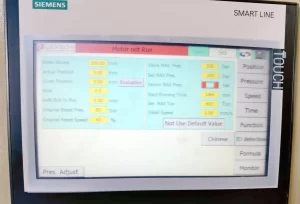

2 of 9Siemens Touchscreen:

Intelligent Jigsaw Puzzle Production Controlled by PLC, with a Ten-Inch Siemens Color Touch Screen.

3 of 9Safety Light Curtain:

The safety light curtains equipped on both sides ensure the safety of workers when placing workpieces and can be optionally complemented with mechanical safety sensors. They provide dual protection through optical and physical sensing.

4 of 9Machine Visual Inspection:

Optional machine vision inspection to detect if there are missing pieces in the jigsaw puzzle.

5 of 9Conveyor Belt:

Adjustable-speed conveyor belt

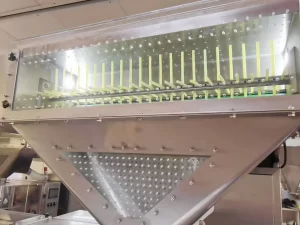

6 of 9Puzzle scattering Unit:

A jigsaw puzzle scatter machine made of silicone rods, which maintains an ultra-high success rate while preserving the puzzle pieces without damage.

7 of 9Puzzle Bagging Unit:

Bagging jigsaw puzzles with heat-sealing PE bags.

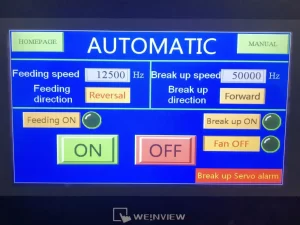

8 of 9Bagging Machine HMI:

The high-definition HMI from Taiwan-based WEINTEK, designed specifically for smart production lines, user-friendly and easy to learn, with adjustable bag length, bag width, and conveyor belt speed.

9 of 9Machine Main Features

- High production speed, cutting a puzzle in just 4 Seconds

- 50% energy saving and noise reduction

- Equipped with state-of-the-art computer control systems

- 50 to 3000 tons of pressure

- The entire stroke speed is adjustable

- Equipped with multiple safety components to ensure worker safety

- Full-body ultrasonic scanning ensures weld seam quality

- Optional vision detection for missing puzzle piece function

- User-friendly and easy-to-learn control system

- Repeatable positioning accuracy up to ±0.01mm

- Pressure error ±1 bar

- Low maintenance cost

- 10-inch high-definition SIEMENS touchscreen

- International top-tier brand premium components

Automated Expansion

- Equipped with an Exchange or Shuttle Table to boost puzzle cutting efficiency.

- Equipped with Siemens PLC, capable of communication and integration with robots.

Enhanced Durability

- Equipped with Austria SKF seals, hydraulic cylinders undergo polishing, heat treatment, and chrome plating, ensuring a leak-free performance for years of continuous use.

- Robust body structure with high-quality mild steel.

- Machine tool structure shot blasting.

- Before Packing, the machine tool undergoes a 72-hour testing period to ensure that all equipment meets 100% quality standards.

Services

- Remote control, management, diagnostics.

- Free training sessions are conducted at our factory in Dongguan, China.

- Expert guidance by well-qualified and experienced engineers for the most suitable machine selection.

- Oversea Engineering support is available.

- Guidance on puzzle die Selection.

Puzzle Making Machine Structure

Lexson Machinery’s Lexson-A01 series puzzle making machine adopts a four-column hydraulic press, which consists of crown weldment, ram weldment, working table, and bed weldment. Compact design with bottom-mounted hydraulic system, reducing footprint and optimizing space utilization.

- The bottom-mounted oil tank design allows for easier cleaning.

- The frame of this hydraulic press is constructed using high-quality and low-carbon heavy-duty steel, ensuring smooth operation and long-lasting durability.

- To achieve the required structural integrity, the frame is fabricated using heavy welded construction techniques, and every weld seam undergoes strict ultrasonic testing.

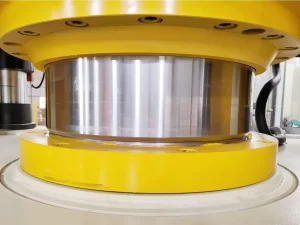

- The main hydraulic cylinder and four columns are made of high-tensile alloy steel that undergoes fine grinding and electro-plating with hard chrome to resist corrosion and wear, ensuring durability and longevity even under high-pressure conditions.

- The Lexson-A01 series of puzzle making machines are designed for decades of service life.

Heavy-duty steel frame. Decades of service Life.

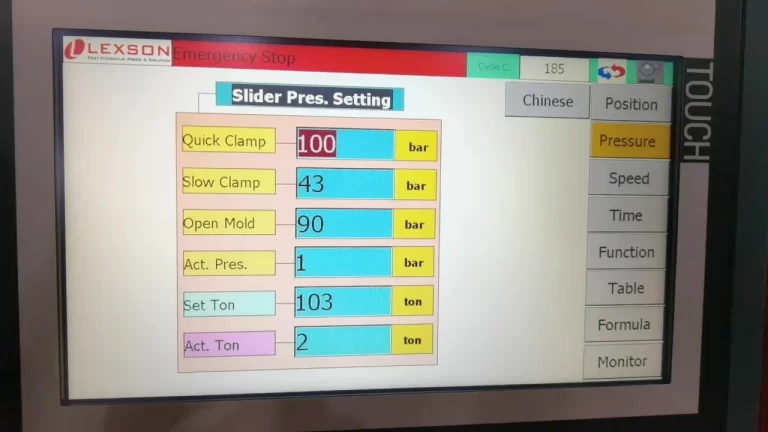

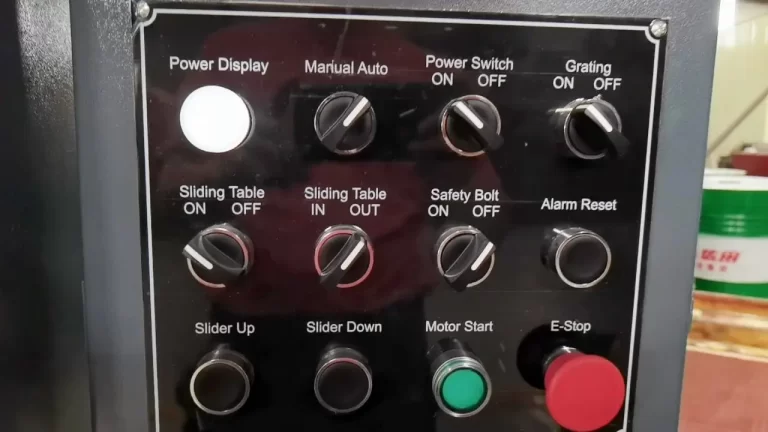

Siemens Operator Panel (HMI)

Our puzzle making machine features a high-definition, high-contrast 10-foot LCD touchscreen panel from Siemens Germany, featuring a user-friendly interface, low learning curve for beginners, large buttons in the operating area, and a top-mounted tricolor indicator light.

Specifically optimized algorithm and pressing action for puzzle manufacturing, ensuring cleaner edges and better molding results. Additionally, the pressing and retraction speed is increased for faster production, significantly enhancing productivity. With these enhancements, our puzzle making machine can maintain an exceptionally high yield of defect-free products, ensuring consistently high-quality output.

- Controlled by PLC, allowing for arbitrary setting of action speed, pressure, and time.

- Multi-stage speed control, first rapid descent, then slow pressing.

- Equipped with “emergency stop” button SB2.

- With a tricolor (green/yellow/red) operation indicator accompanied by a warning buzzer.

- PLC provides reserved for the robot to access the communication endpoint.

- HMI monitors the working process and status of the puzzle making machine throughout.

Intelligent and efficient puzzle production. User-Friendly Interface.

Main Motor

The puzzle making machine is equipped with the latest generation of PHYSIS servo motors from Italy. Replacing the traditional hydraulic system with a servo pump control system. Compared to traditional motors, it is more energy-efficient, has lower noise levels, higher production efficiency, and saves hydraulic oil. The precise control capability of the servo control system effectively improves production efficiency and product quality during puzzle cutting.

- Saves 40-60% energy.

- Reduces noise by 50%.

- Improves production efficiency by 40-60%.

- Saves 50% hydraulic oil.

- Servo motors are very suitable for the continuous high-intensity operation of puzzle making machines.

The latest and most advanced servo motors.

Shuttle table | Exchange table

Lexson Machinery’s Lexson-A01 series puzzle making machine can be optionally equipped with a shuttle table or exchange table, ensuring safer and more efficient puzzle cutting.

- High-precision and high-speed linear guides and ball screws are adopted from HIWIN in Taiwan.

- The sliding table is driven by a DELTA servo motor.

- It has Inching, Single Cycle, and Autorun modes.

- It can be easily integrated into automated production lines, enhancing overall process automation.

- The sliding table is equipped with two-hand start buttons and an emergency stop button.

- The sliding worktable is specially designed for puzzle making machine, reducing puzzle displacement caused by sliding inertia.

High-speed and smooth HIWIN linear guides.

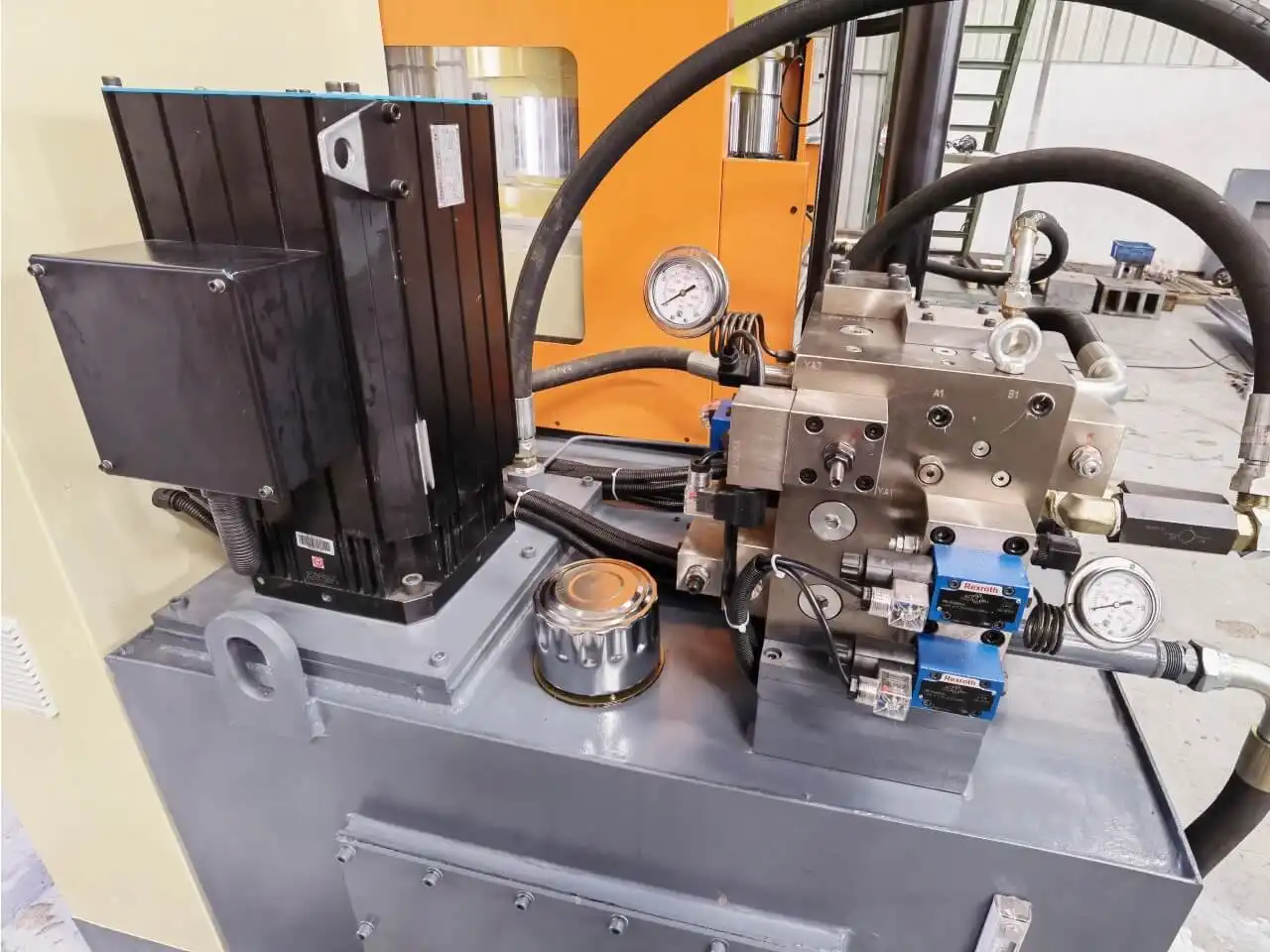

Hydraulic System

The puzzle making machine’s hydraulic system primarily comprises an oil pump motor unit, master cylinder integrated valve, pressure gauge, pressure sensor, and oil tank. All accessories of the hydraulic system are sourced from top international brands. The hydraulic pump is sourced from ECKERLE (or SCENERY) in Germany, the hydraulic valves are sourced from Bosch Rexroth in Germany, the pressure is sensor sourced from GEFRAN in Italy, and the hydraulic seals are sourced from SKF in Austria.

- The closed-loop control system ensures continuous monitoring and removal of defects throughout the puzzle pressing process, significantly reducing the scrap rate.

- Designed for high resistance to oil contamination.

- With shorter connection pipelines and fewer release points, it significantly reduces the risk of oil leakage.

- Equipped with overload overflow protection.

- The piston rod of the cylinder is chrome-plated after undergoing heat treatment, enabling it to operate reliably under high pressure.

- Oil tank’s front-side liquid level thermometer for level and temperature observation.

- The hydraulic oil tubes use VITON fluororubber from the United States, and they exhibit excellent durability and sealing properties.

- The hydraulic system has oil-water cooling.

Leak-proof and oil-resistant, ensuring decades of stable and safe operation.

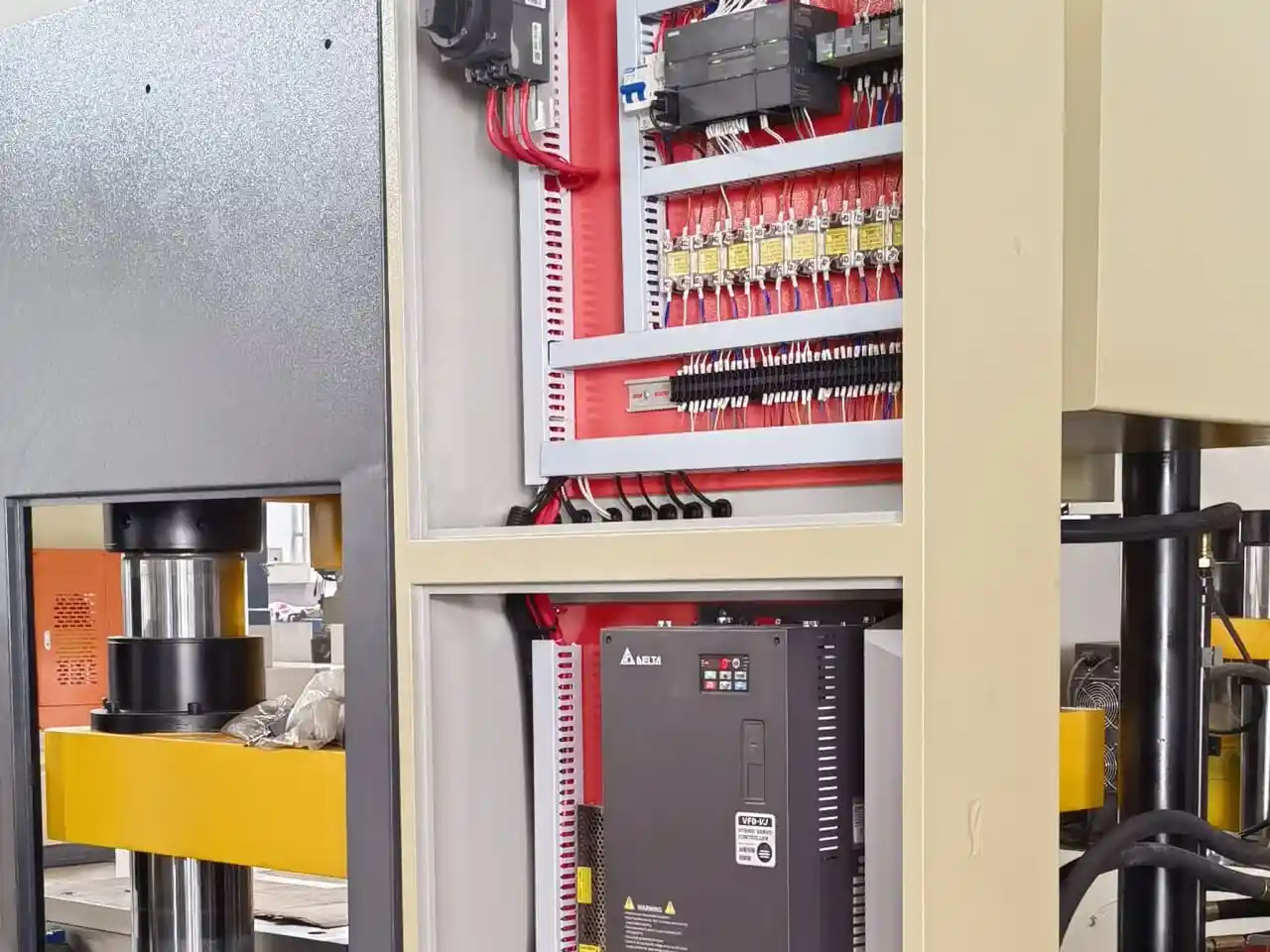

Electrical Parts

Lexson Machinery’s Lexson-A01 series puzzle making machine adopts Schneider’s electrical components from France, providing top-notch performance, stability, and safety. The electric cabinet is designed in NEMA style and features an electric disconnect switch and a cooling system.

The servo drive, sourced from Inovance in China, is a top-tier manufacturer of drives, ensuring precise and efficient motion control, further enhancing the overall performance and reliability of our puzzle making machine, allowing for precise control over pressure, speed, and position.

Internationally standardized electrical components, easy replacement.

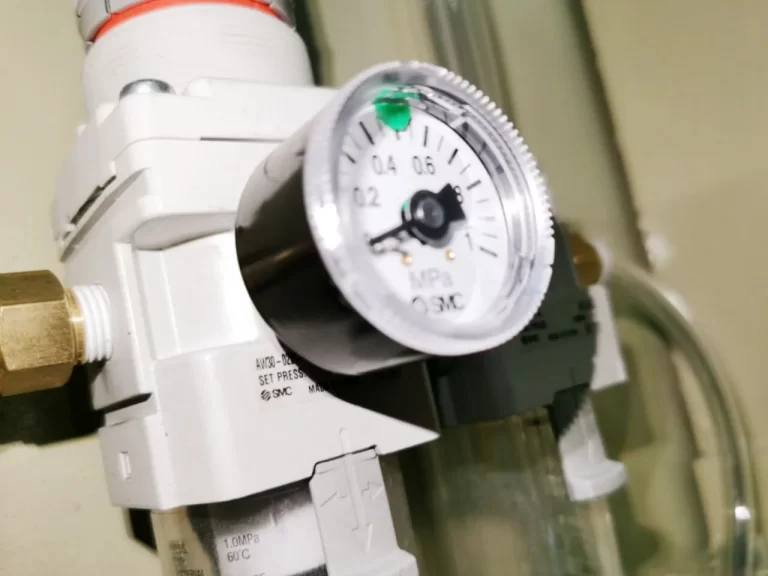

Safety Systems

Our puzzle making machine is equipped with multiple safety measures, meeting the export standards of various countries. Lexson Machinery has always regarded ensuring personnel safety as the top priority in puzzle cutting.

- Adopting SMC cylinder drop prevention from Japan eliminates the safety hazards caused by cylinder depressurization.

- Equipped with metal safety guards on both sides, which is compliant with CE standards.

- Two safety light curtains cover the workpiece feeding area.

- Two-hand optical touch button (USA BANNER) or physical start button (France Schneider).

- Equipped with front and back emergency stop buttons, it allows for an emergency shutdown at any stage of the puzzle pressing process.

- The hydraulic system is equipped with a safety valve, which automatically diverts overflow when the oil pressure exceeds the set value.

- Equipped with a mechanical safety sensor, which ensures the safety of workers during the process of placing workpieces. It serves as an additional safety measure beyond the safety light curtain.

- Our puzzle making machine is manufactured adhering to the highest safety standards.

8 safety components, ensuring safe production.

FAQ

What is a puzzle making machine?

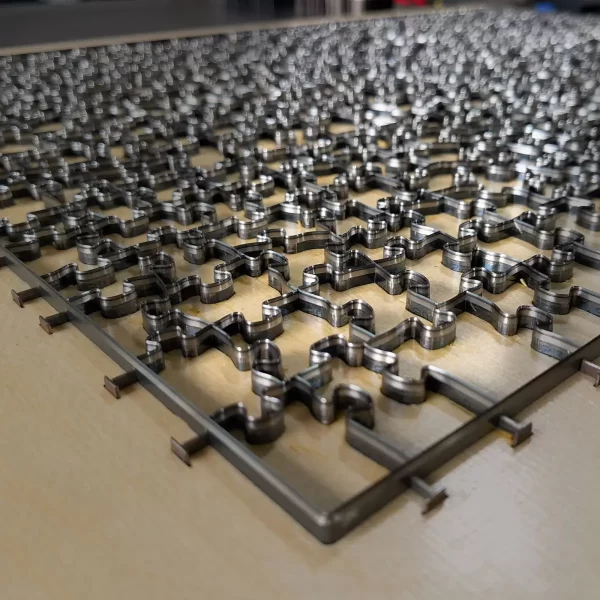

"Puzzle making machine," also known as a "puzzle cutting machine" or "puzzle press", which is an industrial machine that utilizes hydraulic pressure and a steel rule die to press puzzles into specific shapes. It is currently the mainstream solution for mass-producing puzzles in large quantities.

What type of hydraulic press does your puzzle making machine use?

Our puzzle making machine adopts a four-column hydraulic press, known for its stable structure and large working table area, making it highly suitable for puzzle cutting applications.

What are the differences between your puzzle making machine and those from other manufacturers?

Our puzzle making machine is distinct from other hydraulic press manufacturers. It is specifically optimized and tailor-made for puzzle production, with over twenty years of refinement and multiple iterations. It encompasses a complete set of solutions, including hydraulic press, puzzle bagging machine, and steel rule die, making it a truly high-end intelligent production line for puzzles.

How long does it take to learn to use this machine?

Our machine's Human-Machine Interface (HMI) is simple and easy to learn. Typically, it only takes a few hours to grasp the basic operations, and a few days to become fully proficient. The learning and training costs are low. The Lexson series of machines make puzzle cutting simple and efficient.

What is the warranty period?

We provide a one-year warranty for the entire machine. During the warranty period, damaged components will be replaced free of charge. The hydraulic cylinder, bed, and frame (beam) are under a 3-year warranty.