Custom 4-Post Hydraulic Press

Youtube Video

Four Column Press Parts

Only the highest quality components are used

Anti-drop Cylinder Equipment:

Equipped with anti-fall cylinder equipment from SMC Japan, significantly improving safety in case of pressure loss.

1 of 8Hydraulic Columns:

high-strength chrome-plated columns and replaceable graphite impregnated bronze bushings, equipped with Austrian SKF hydraulic seals to ensure ultra-long durability.

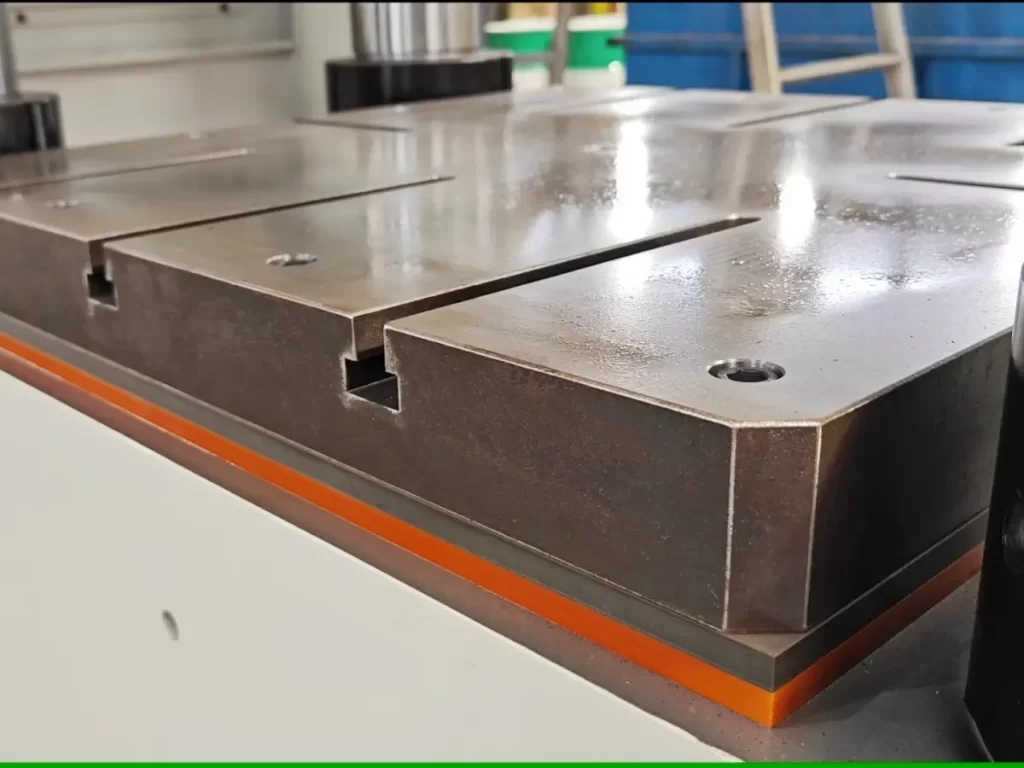

2 of 8Workbench:

The 4-post hydraulic press can be equipped with various types of workbench to meet diverse production needs, such as T-slots, movable workbench, heated workbench, middle ejector cylinders, shuttle workbench, or exchange workbench, among others.

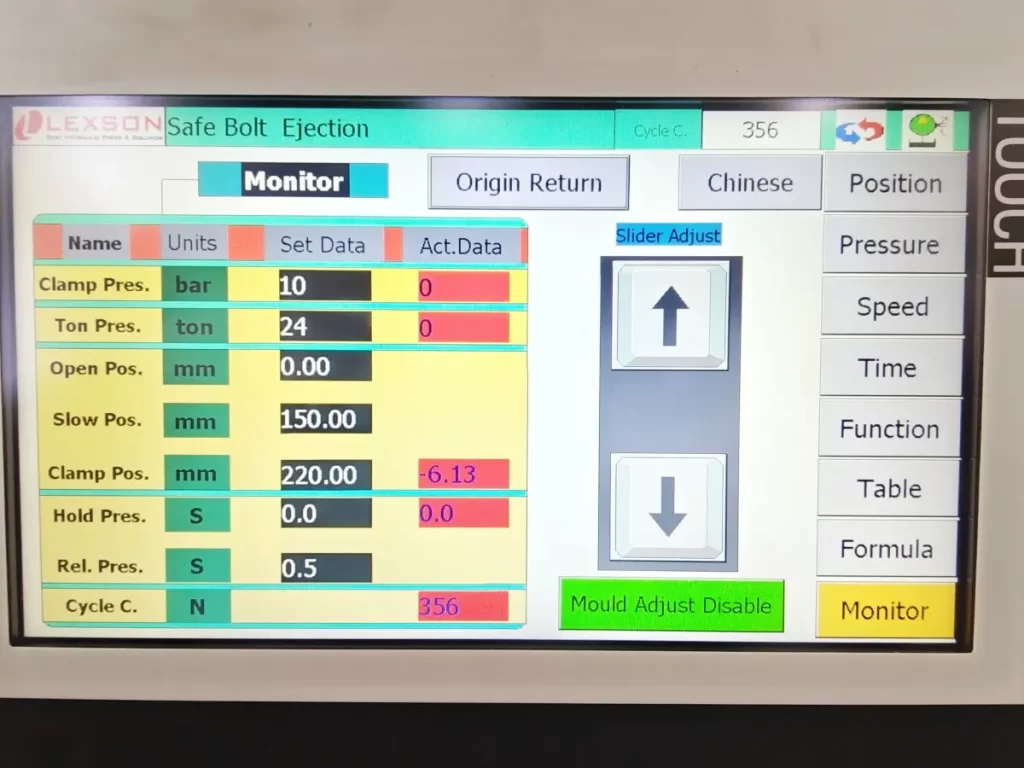

3 of 8Control Unit:

The main control unit is from Siemens Germany, providing a comprehensive, user-friendly, and intelligent control system.

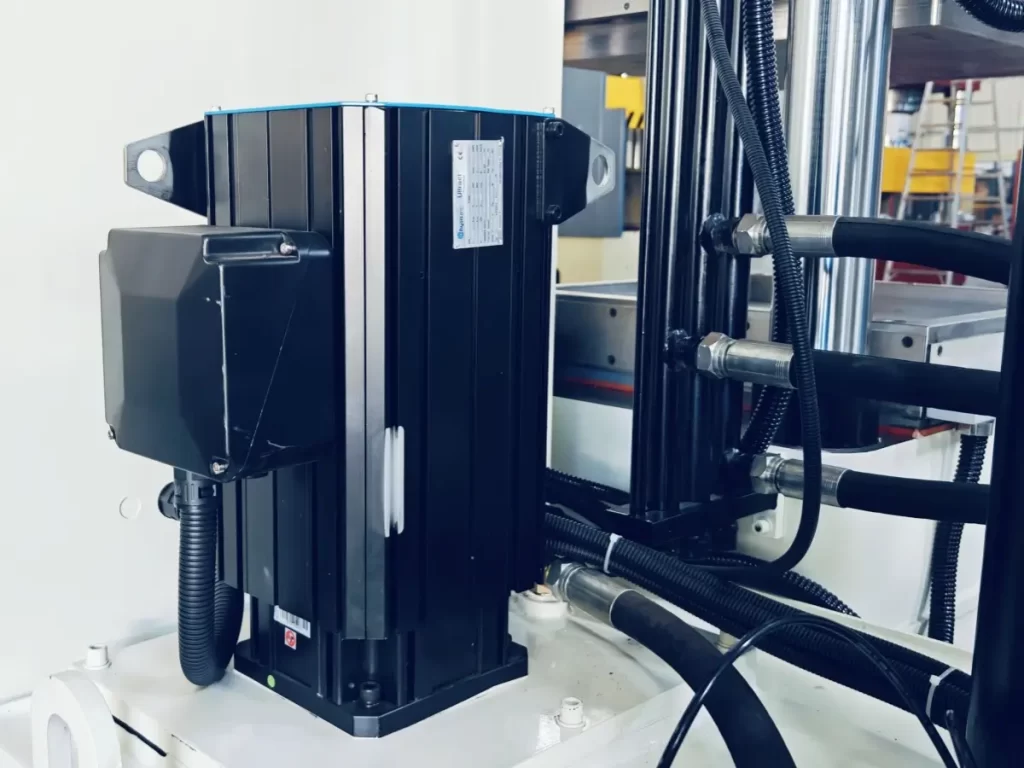

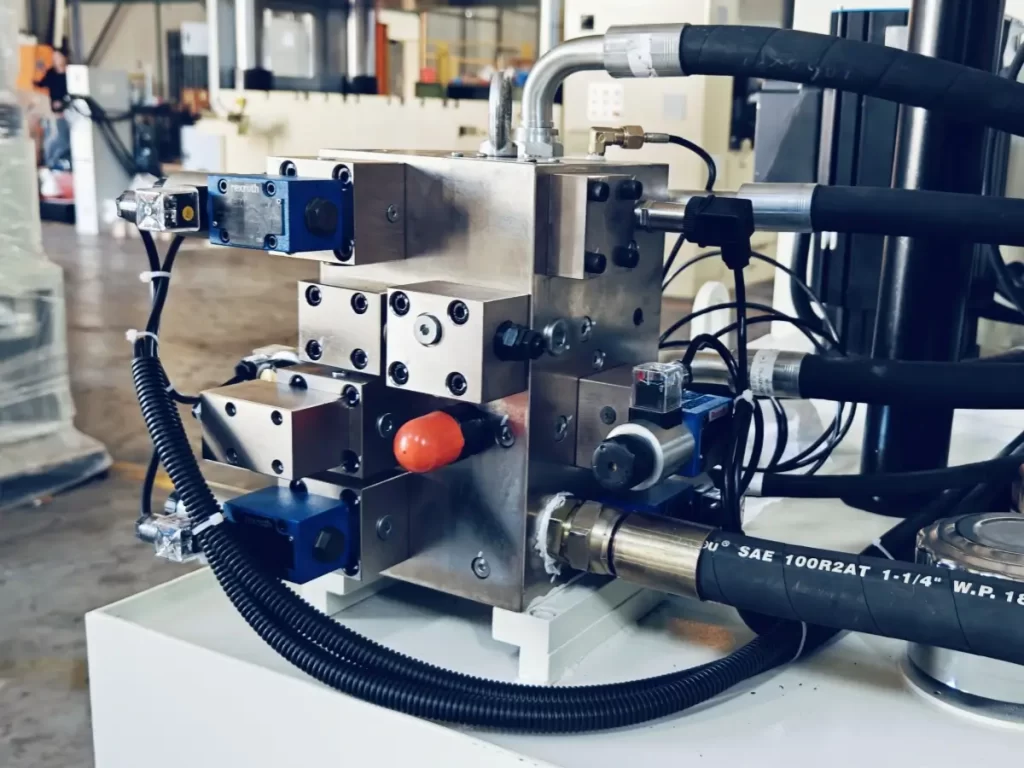

4 of 8Hydraulic Valves and Servo Motor:

Equipped with Bosch Rexroth hydraulic valves from Germany, offering the industry’s top fluid flow control capability. Equipped with a permanent magnet servo motor from PHYSIS, Italy, providing a silent, energy-saving, and stable power source.

5 of 8Electrical Components:

Equipped with electrical components from Schneider France.

6 of 8Dual-hand Start Buttons and Emergency Stop Buttons.

7 of 8Hydraulic Oil Tank and Level Indicator.

8 of 8Technology and Application

Stamping

Using a 4-post hydraulic press to stamp metal materials into specific shapes through molds. This method is often used to produce automotive bodies, home appliance casings, and more.

Stamping PressHeat Pressing

Ideal for thermosensitive materials and composite material heat pressing due to its flexibility and customizability. Heated platen presses commonly utilize 4 post hydraulic presses.

Heated Platen PressTrimming

The 4-post hydraulic press is also often used for trimming, as its workbench area is large, the force is evenly distributed, and it is convenient to load and unload workpieces, easily covering trimming of small to large castings.

Trimming PressDeep Drawing

The high stability and superior guidance accuracy of the 4 post hydraulic press are crucial for preventing wrinkles and cracks during the deep drawing process, making it widely used in this technique.

Forming

Due to its high stability and even pressure distribution, the 4-post hydraulic press excels in various forming processes, including thermoforming, cold forming, compression molding, bending, and shaping, to produce parts of diverse shapes and sizes.

Others

The 4-post hydraulic press is the most widely used type of hydraulic press, they are also commonly used in powder metallurgy, punching, bending, die-cutting, and more.

Puzzle Making Machine4-Post Hydraulic Press Details

- Machine parameters can be customized

- Exceptionally high cost-performance ratio

- Pressure range from 10 tons to 10,000 tons

- Pressure accuracy within ±1 bar

- All components are from top brands

- High-strength, heavy-duty machine frame

- User-friendly SIEMENS touchscreen

- Low maintenance for long-term operation

- Lifespan of the machine spans decades

- Servo motor speed increased by 30%

Machine Structure

Our 4-post hydraulic press uses ultra-heavy steel weldments to significantly reduce frame deformation, defaulting to a three-beam four-column structure, allowing the workpiece to be flexibly inserted from all four sides. The hydraulic system, industrial control components, and body are set up independently for easy maintenance.

- Tonnage range from 10 tons to 10,000 tons.

- The number of main hydraulic columns can be configured as needed.

- Machine size, color, work area dimensions, stroke speed, and other parameters can be customized.

Power Unit

The power unit of Lexson Machinery’s 4 post hydraulic press includes a hydraulic pump, permanent magnet servo motor, oil tank, and auxiliary components like filters, coolers, and pipes. All power components use first-line brands, characterized by energy-saving, silence, stability, and lower hydraulic oil temperature. It converts electrical energy into mechanical energy with high energy efficiency, continuously providing strong and stable power output.

- Equipped with a German ECKERLE hydraulic pump for high-efficiency energy conversion, providing stable pressure and flow.

- Equipped with an Italian PHYSIS permanent magnet servo motor for faster response, higher efficiency, lower noise, and vibration.

- Hydraulic pipes use high-performance rubber from American VITON.

Control and Hydraulic Systems

Our 4-post hydraulic press’s control and hydraulic systems include a control panel, hydraulic valve group, and various sensors. They regulate the pressure, speed, and direction of the hydraulic press, forming a full closed-loop control with the power system for a quick-response control experience, ensuring the machine operates at its best state.

- Equipped with a German Bosch Rexroth modular hydraulic valve group for higher integration and lower maintenance costs.

- SIEMENS intelligent series control panel for more intuitive and convenient operation.

- Modular hydraulic system enhances efficiency and hydraulic oil sealability.

- Control system equipped with fault self-diagnosis.

- Compact hydraulic system design, strong anti-vibration capability.

- Equipped with Italian GEFRAN pressure sensors.

- Equipped with a Chinese INOVANCE servo drive to significantly enhance the performance and efficiency of the hydraulic press.

Workbench (Multiple Types Available)

Lexson Machinery’s 4-post hydraulic press is widely applicable, with a variety of workbench configurations available for customization to meet high-standard processing requirements.

- T-slot (optional).

- Movable workbench (optional).

- Heated workbench (optional).

- Middle ejector cylinder (optional).

- Shuttle table or exchange table (optional).

- Automation for loading and unloading workpieces (optional).

Safety System

Our 4-post hydraulic press is equipped with multiple safety systems, with the primary consideration in design being to ensure safe production.

- CAT4 level safety light curtains.

- Three-color indicator lights and buzzer alarm.

- Equipped with dual-channel safety relays, relief valves, and safety valves to ensure the safe and stable operation of the hydraulic system.

- Dual-channel emergency stop buttons.

- Japanese SMC hydraulic cylinder fall protection equipment.

- Full process monitoring log.

NEMA Type Electrical Components

Lexson Machinery’s 4 post hydraulic press is equipped with electrical components from Schneider, France, ensuring operational safety and environmental protection.

- Standardization and modularization of Schneider components make the hydraulic press’s maintenance, replacement, and upgrade more convenient and faster.

- Integrated with advanced safety components, significantly improving the operational safety of the hydraulic press.

- Dustproof, moisture-proof, and high-temperature resistant.

FAQ

What is a 4-post hydraulic press?

A 4-post hydraulic press is a widely used hydraulic pressure equipment. Its core feature is the four-column structure, primarily used in industrial fields for processes like stamping, forming, die-cutting, deep drawing, and press fitting. The 4-post hydraulic press offers higher stability and anti-eccentric load capability, making it more reliable for medium to large part processing.

How long is the warranty period for the 4-post hydraulic press? What does the warranty cover?

Our hydraulic press comes with a one-year warranty for the whole machine and a three-year warranty for the machine frame. During the warranty period, damaged parts of the machine will be replaced for free, and cost-price replacements are provided for out-of-warranty parts.

What is the lifespan and durability of the 4-post hydraulic press?

Our hydraulic presses are made for long-term use. With its multiple anti-oil leakage designs and the main hydraulic cylinder designed for millions of cycles, Lexson Machinery's machines generally have a lifespan of over ten years with low maintenance.

What are the main application fields of the 4-post hydraulic press?

The 4-post hydraulic press is widely used in metal processing (such as stamping, deep drawing, bending), thermoforming, cold forming, powder metallurgy, rubber vulcanization, and many other industrial fields.

What are the characteristics of the 4-post hydraulic press?

Its main features include stable structure with even force application, wide pressure range, broad application scope, and high cost-performance ratio.

Maxim Ivanov –

We’ve used this press for several heavy-duty projects, and it has performed exceptionally well.

Antonio García –

As a small business owner, I was looking for something affordable yet efficient, and this 4 post hydraulic press did not disappoint.

Ivan Kovač –

The 4 post hydarulic press is a significant investment that pays off in the quality of work.

David Lee –

This customized 4-post hydraulic press has increased my production efficiency by 30%. Many thanks to VELXUN and Lexson Machinery.

Charles Dupont –

When I had issues with a part, the customer service was prompt and helpful. They sent a replacement quickly, and it was easy to install.

Carl Eriksson –

It’s incredibly robust and has handled everything we’ve thrown at it with ease. The precision it offers is top-notch!

Jack Nowak –

This 4-post hydraulic press is capable of handling large and complex parts with ease, and its precision is unmatched.

Florian Müller –

It’s incredibly robust and has handled everything we’ve thrown at it with ease. The precision it offers is top-notch!

Aiden O’Neill –

This hydraulic press is a powerhouse!

Adrian Schmidt –

This 4-post press is compact but doesn’t compromise on power or efficiency. Definitely a smart design.

Leo Johansson –

The 4-post design offers excellent stability and distribution of force, which is perfect for my larger projects.